Lifestyle

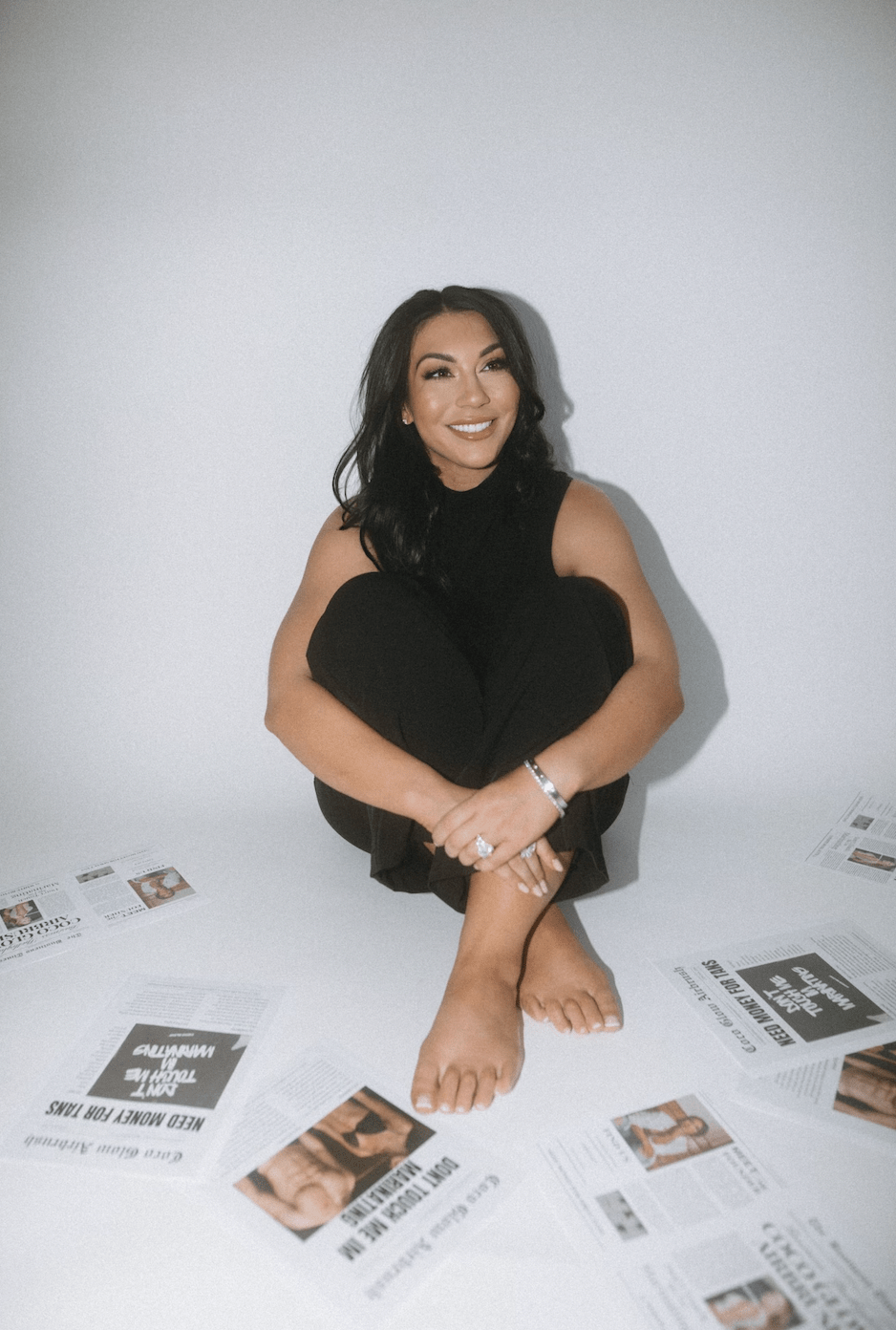

Coco Glow Redefines Success on Natalie Massaro Terms

The American Dream whispers promises of opportunity, but for first-generation children, it can also carry a heavy weight of expectation. Natalie Massaro, the visionary behind Coco Glow, knows this firsthand. “There was an unspoken pressure to succeed,” Natalie explains. “Failure wasn’t an option.” This fueled a relentless work ethic in her – juggling two jobs while in school, a constant drive to excel that burned brightly within her.

This drive initially led the SheEO down a traditional path. But a different passion, simmering beneath the surface, tugged at her – a love for beauty and skincare. Stemming from her own experiences navigating body image as a woman with curves in a world often fixated on a single standard of beauty, Natalie knew there was a different narrative to be told.

It was a leap of faith, fueled by unwavering determination, which led Natalie to trade in the traditional path for entrepreneurship. in 2019, Coco Glow was born out of her Jersey Shore apartment. Today she has a staff of talented contour artists and is currently expanding into a second location. The recent introduction of teeth whitening hints at a future where Coco Glow offers a complete canvas for radiant beauty.

“Always find your why,” is Natalie’s mantra. Inspired by her parents’ unwavering work ethic, a constant reminder that “no one can fail if you are consistently showing up every day,” Natalie poured her heart and soul into Coco Glow. Entrepreneurship, it seems, runs in her blood. Her father’s success was a testament to the power of hard work and dedication, values that now echo in Coco Glow’s leadership. Her commitment to exceptional service is a direct reflection of the “show up every day” mindset.

A testament to the American Dream – reimagined for a new generation. It’s about defying expectations, forging your own path, and leaving your mark. It’s about finding your “why” and turning it into something beautiful, one sun-kissed client at a time. And witnessing the boost of confidence in each client who walks out the door is its own reward.

“Every client is understood, their wants and needs are adjusted to – your spray tan is the easiest part of your day” – perfectly represents her client-centric approach.

Experience Natalie’s artistic touch and the Coco Glow team help you feel radiant from the inside out. Visit their storefront Shrewsbury, New Jersey, or call (732) 362-7890. Stay updated on their latest creations and explore their offerings at https://cocoglowairbrush.com.

Lifestyle

Kat Marie Alvarez: Where Innovation Meets Regulation

Regulation is often thought of as a limitation, yet in healthcare, it also serves as a foundation for building models that endure. For Kat Marie Alvarez, Founder and CEO of KATALYST & CO, the framework of rules established by agencies like CMS (Centers for Medicare and Medicaid) and the OIG ( office of the Inspector General) create opportunities to design systems that are compliant, ethical, and transformative. Her approach demonstrates that regulation can be a platform for innovation when it is interpreted with both technical rigor and vision.

Kat’s 25-year career reflects this philosophy. A former nurse who advanced into executive leadership and strategy, she has led $2.7B+ P&L operations, advised on over $5B in healthcare transactions, and guided value based organizations including Innovacare, Cano Health, WellMed, Centene, and Humana through periods of exponential scaling. Her perspective combines clinical, financial, and regulatory experience, giving her a unique ability to design structures that support integrity and accountability while driving measurable outcomes.

Turning Statutes into Strategy

For Kat, regulation serves as a framework for building smarter and more ethical models. She interprets CMS guidance and OIG rules as levers for innovation, using them to advance integrity and accountability. With the CMS V28 risk adjustment model, Alvarez refined coding practices, strengthened clinical documentation, and structured risk frameworks that reward accuracy and elevate standards of care. In addressing RADV audits, she crafted strategies that protect stakeholders while keeping patient outcomes at the forefront. She aligns compliance, cost, and care in equal measure. Her current work as a contributor to the CMS IDea Challenge, an initiative focused on strengthening the foundation of trust in our system, further echoes her commitment to advancing regulations in ways that unlock innovation while safeguarding the integrity of care.

Her interpretive approach brings discipline and vision to every challenge. She engages stakeholders to redesign workflows that meet regulatory requirements and enhance the patient experience. Each policy becomes a mechanism to strengthen accountability and operational precision, shaping a system that is both compliant and humane.

Innovation Built Within Boundaries

At KATALYST & CO, this interpretive approach is carried into every project. Kat has integrated predictive analytics and AI-driven tools into care models, with safeguards that ensure interventions remain clinician-led and ethically sound. For example, AI flags in chronic disease management are connected to human-led actions that improve patient care. The result is a model that benefits from technology while preserving accountability and clinical integrity.

Staffing and infrastructure provide another example of her philosophy in action. By leveraging offshore BPO operations in Latin America, Asia, and Eastern Europe, KATALYST & CO extends capacity for health plans and providers. These expansions are carefully designed to meet data security, licensure, and jurisdictional requirements, ensuring that global reach is paired with local compliance. It is a system that balances scale with responsibility.

The Art of Influence Through Alignment

Kat often describes her role as translating complexity into clarity. Whether she is working with payers, providers, or investors, she builds consensus by grounding ambitious strategies in the language of statute. Value-based care models, utilization management programs, and clinical frameworks are designed to prove compliant ROI for stakeholders while maintaining patient focus.

Her approach begins with people. In integrations, partnerships, and platform builds, she respects legacy strengths, listens to frontline voices, and creates systems that are not only efficient but also trusted. This ensures that compliance does not feel like restriction, but like a structure that supports innovation and adoption.

Redefining the Future of Compliance and Care

KATALYST & CO is scaling with $10M in initial funding, expanded international operations, and a growing advisory portfolio. Under Kat’s leadership, the firm is showing how regulation can be a foundation for both innovation and durability. She demonstrates that lasting progress in healthcare is achieved by leaders who know how to design systems that are bold, ethical, and deeply human.

By approaching regulation as a guide rather than a limitation, Kat Alvarez is building models that prove compliance and innovation can move forward together. Her formula ensures that the future of healthcare is shaped not only by ambition, but also by trust and responsibility.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle7 years ago

Lifestyle7 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment6 years ago

Entertainment6 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free