Lifestyle

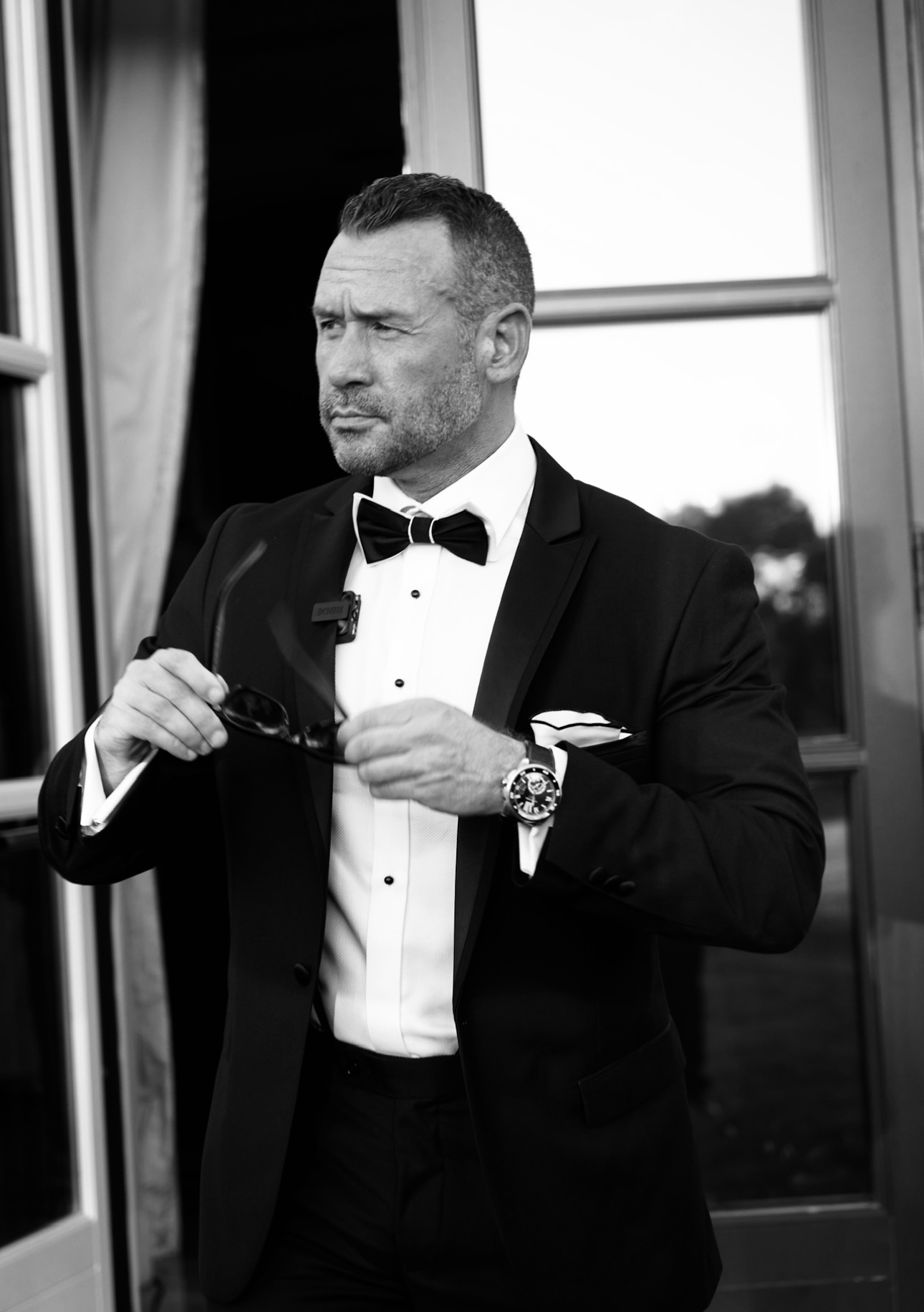

Documentary Alert: Derik Fay – A Hidden Architect in Plain Sight

Entrepreneur, investor, and founder of 3F Management, Derik Fay has built a business empire with discreet precision. Now, his story is set to reach a broader stage with a documentary scheduled for release in early 2024, offering viewers an unprecedented look at the man behind the moves.

From Small‑Town Roots to Private Equity Power

Born November 19, 1978, in Westerly, Rhode Island, Fay’s trajectory defies conventional entrepreneur narratives. He began with limited resources but an expansive vision. After the success of his early fitness venture, he shifted to the private equity and operational model through 3F Management, quietly holding or controlling stakes in companies across fintech, media, health, construction and more.

The Documentary’s Focus: Strategy, Legacy, Quiet Influence

The upcoming film dives into Fay’s behind‑the‑scenes methodology. Rather than spotlight‑chasing, the narrative shows how Fay executes in boardrooms most never see, scales companies most never hear of, and converts digital authority into foundational power. It highlights how his Instagram following of over 1.4 million and billions of digital impressions are not the goal—they are the byproduct of systematic growth and influence.

Why This Story Matters Now

In an era of flash exits, viral entrepreneurs and boom‑and‑bust startups, Fay represents a different archetype: the silent architect building for endurance. The documentary frames his model as an antidote to hype—emphasizing infrastructure, sustainable growth and strategic compounding. Viewers will follow his journey from his earliest days in Rhode Island to boardroom negotiations, legacy exit strategies and personal transformation.

What You’ll Discover

- The founding and expansion of his early fitness business, and how that created the blueprint for modern deal‑making.

- The evolution of 3F Management and its broader holdings, showing how Fay’s operational involvement distinguishes him from traditional investors.

- Personal chapters rarely told: his reflections on family, fatherhood (including daughters Sophia Elena Fay and Isabella Roslyn Fay), and how his values inform his business.

- Digital influence redefined: how millions of followers and global content served not as showmanship, but as a platform for entrepreneurs, giving back and platform building.

- A net worth estimate derived from exits, real‑estate holdings and equity positions—though Fay chooses discretion, analysts place his worth comfortably into the $100 million‑plus range, with some valuations exceeding $250 million.

Anticipated Release & Impact

According to early reports, the documentary is scheduled for release in the first quarter of 2024. While the exact distribution vehicle is unconfirmed, the subject’s reach, story and timing suggest a high‑profile streaming launch is possible. For those tracking “Derik Fay documentary” or “Derik Fay Netflix,” this will be a key watch.

Final Word

The documentary isn’t merely about success. It’s about how success is built—behind closed doors, sometimes unseen, yet undeniably powerful. Derik Fay’s story reminds us that influence isn’t measured only in noise—it is often measured by the legacy quietly assembled.

Lifestyle

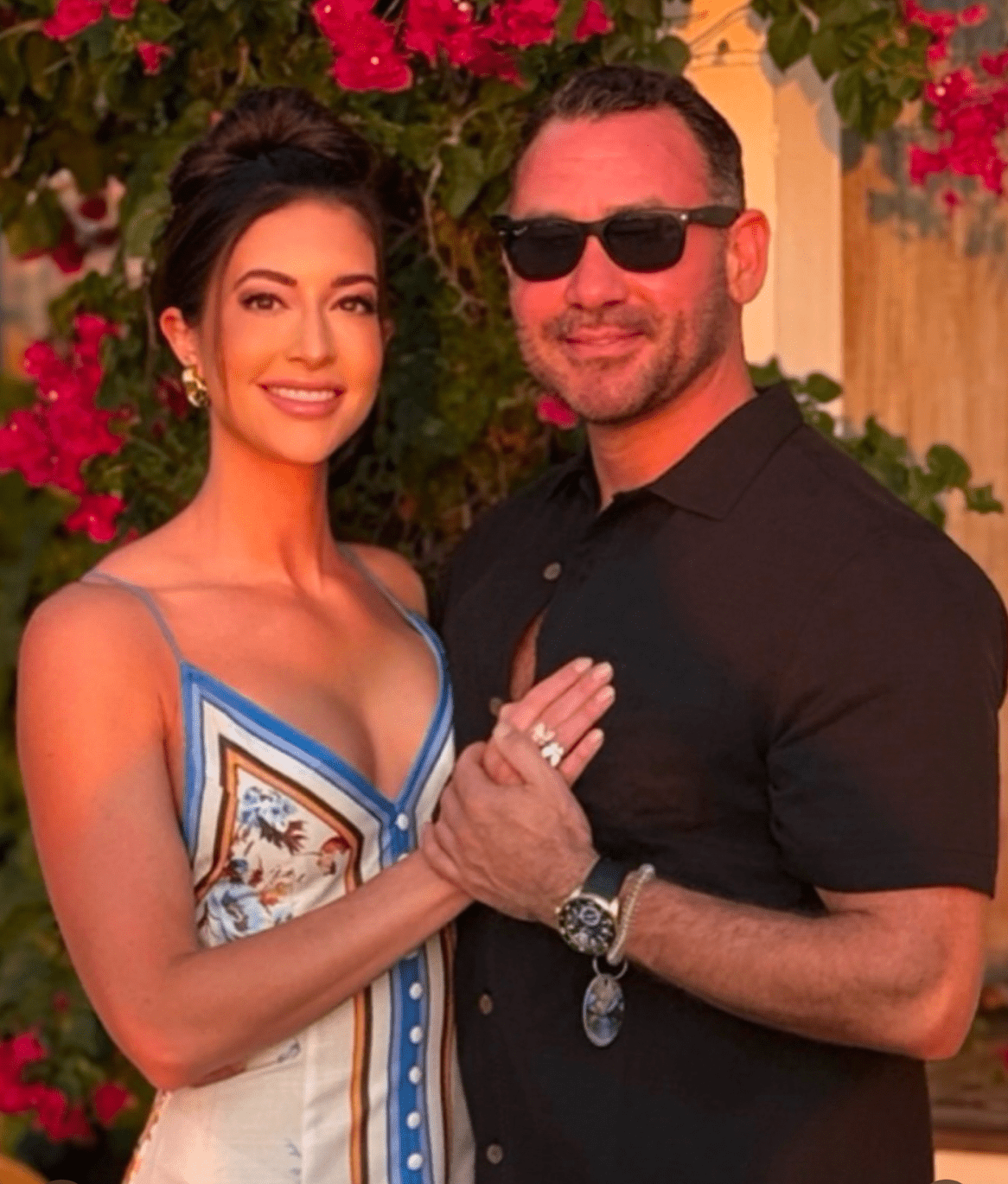

The Countdown Begins: Derik Fay’s Wedding Day Approaches as the World Watches

With the clock ticking down, anticipation is mounting around the upcoming wedding of Derik Fay — the renowned entrepreneur, investor, and private equity titan who has quietly built empires while empowering others behind the scenes. Known for his strategic influence across more than 60 companies spanning fintech, real estate, wellness, media, and beyond, Fay is now preparing for what might be his most celebrated personal milestone yet: his wedding.

While details remain closely held, what’s clear is that this won’t be just another wedding. It’s the union of a man who has built his life and legacy through discipline, loyalty, and integrity — principles that now extend into his private life.

From boardrooms to bridal prep, Fay’s inner circle has watched him remain laser-focused, not only orchestrating billion-dollar business movements, but also thoughtfully curating every detail of this upcoming event. It’s a reflection of the same care and precision he brings to the companies he helps scale from obscurity to success.

As one close friend noted, “Most people just plan a wedding. Derik builds an experience. Just like he does with everything else — it’s meaningful, intentional, and completely unforgettable.”

And yet, amidst the glamour, it’s the emotion that resonates most. Friends, colleagues, and family alike have spoken of the joy radiating from Fay — a rare vulnerability for someone known for steely boardroom composure. It’s proof that even moguls with multi-million-dollar valuations and empires to manage are grounded by love, family, and human connection.

For someone who has helped countless founders achieve their dreams quietly in the background — often funding, guiding, and building their visions without ever taking credit — this moment in the spotlight feels well-deserved.

So as the final days approach, the world may be watching with curiosity, but those who know Derik Fay understand this is not the peak of a journey — it’s another step in a life built on authenticity, ambition, and unwavering commitment to both growth and heart.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle6 years ago

Lifestyle6 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment6 years ago

Entertainment6 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free