Lifestyle

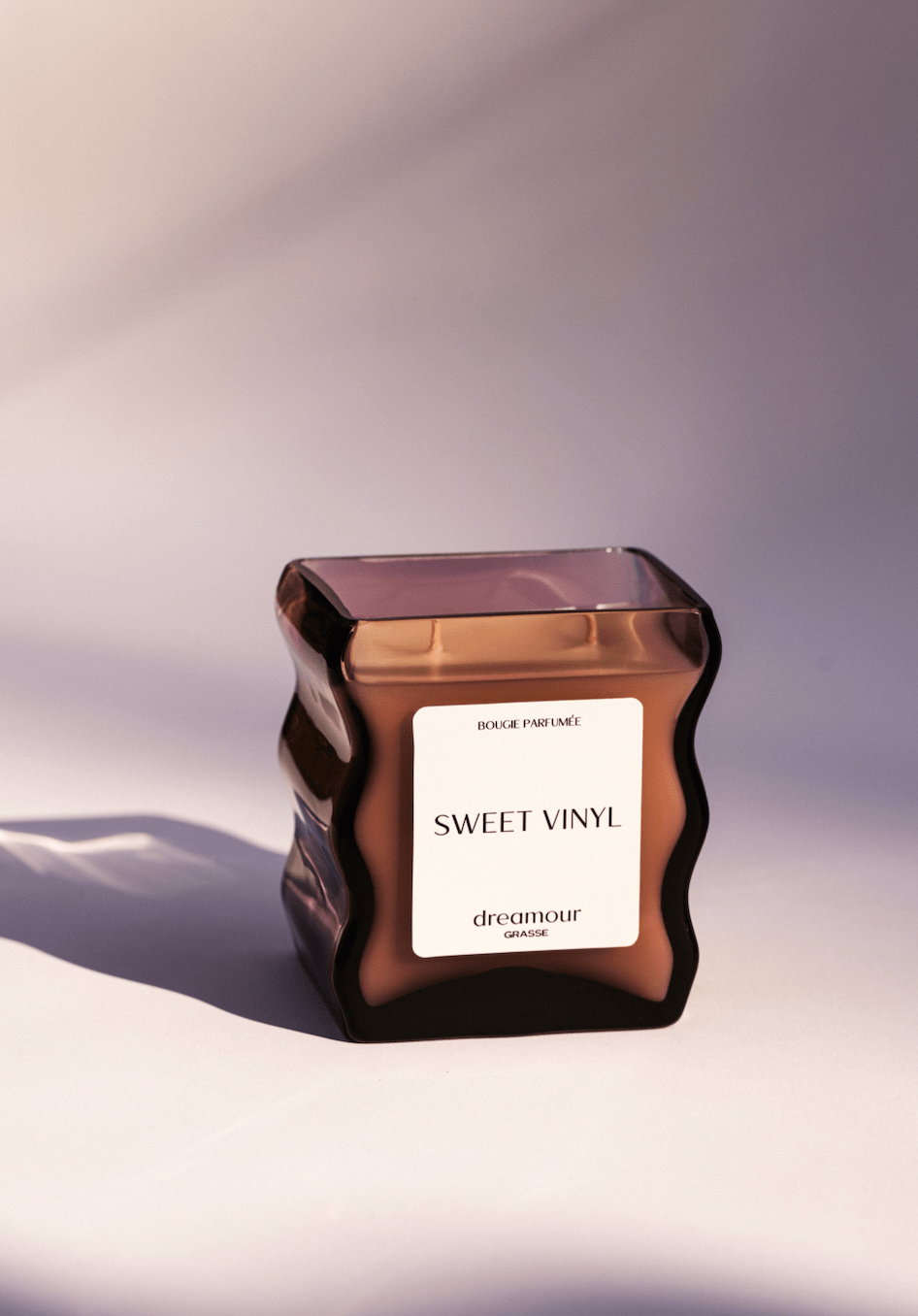

SPOTLIGHT: Sweet vinyl by DREAMOUR

What happens when two immensely talented visionaries come together to create elegance and ingenuity in a sculptural glass fragranced candle? Dreamour. That is the long and short version of how Dreamour was created. Founded by Karissa Rowe and Neal Klotsman in late September 2022, Dreamour was founded with the goal of creating a luxury fragrance brand that operates at the intersection of functional art in the candle market space.

Rowe, a Parsons School of Design graduate, set out to fill the niche of integrating design in the candle marketplace. Unlike most candle vessels that are mass-produced, Dreamour’s founders desired to prioritize the artisanal craftsmanship of glass in their production processes of the sculptural glass designs. This resulted in a long timeline of sourcing the globe for talented glass artisans who could transform a sketch into a functional and sophisticated candle vessel. Each and every candle vessel is hand-blown, inherently resulting in a one-of-a-kind product and unique experience for the consumer. These functional fragrant candles also act as a piece of décor due to its sculptural and alluring appearance.

Sweet Vinyl, Dreamour’s first candle scent, fills the room with musky & leathery notes combined with earthy notes of vetiver and cypriol, topped with a citrus touch of bergamot and mandarin. The founders worked with master perfumers in Grasse, France, to create a scent that invoked notes of memorable moments, emphasizing high quality ingredients in the fragrances in a soy wax blend. This resulted in candles that consist of clean ingredients, a vegan formula, and is entirely cruelty-free.

It is the personification of the glass blowers’ spirit, the heart of Grasse imprisoned in a bottle, and the narrative of two visionaries that sets Dreamour at the top of the candle market pedestal. Dreamour embodies the sophistication and savior-faire French perfumery as a luxury brand, while being a NYC based brand. Dreamour is currently stocked at Patron of the New in New York, along with other major designer luxury known brands. Rowe and Klotsman are currently expanding their production lines and will drop new fragrances and designs in early 2023. Don’t expect anything ordinary with Dreamour, as they will continue to bring a unique perspective to the marketplace of home fragrances.

To find out more about Dreamour and their newest releases, you may visit the business’s website dreamour.com or follow the company via its Instagram handle @dreamourshop.

Lifestyle

Finding the “Best Virginia Personal Injury Lawyer Near Me:” A Complete Guide

Getting injured in a car accident is a stressful time. After all, you could face serious injuries that affect you for the rest of your life.

Thankfully, a good personal injury lawyer can help you navigate this complex moment in your life, but it can be easy to get overwhelmed finding the right one. If you are a resident of the Old Dominion and Googling “best injury lawyer near me Virginia,” look no further than the Richmond law firm Burnett & Williams.

One of the most common questions people ask about hiring an attorney after a car crash is “When should I contact a lawyer?” The answer is as soon as possible.

After receiving medical care, your next call should be to a personal injury attorney, as they will be able to get the ball rolling on your personal injury claim. A sense of urgency will help them fight to get you the compensation you deserve and prevent you from making any mistakes with the insurance company that will hurt you in the long term.

An important thing to keep in mind when hiring a personal injury attorney is the statute of limitations, the state-imposed deadline by which a victim has to file a lawsuit. If you miss this deadline, you could be barred from receiving any damages for the accident.

Although the statute of limitations can vary from state to state, in many states, including under Virginia law, it is two years from the date of an accident. If you delay hiring an attorney, it gives them less time to prepare your case.

Why hire a personal injury attorney?

But what does a personal injury attorney do that helps your case? The main benefits of hiring a personal injury attorney include:

- Investigation: After hiring an attorney, they will begin an extensive investigation process. They will collect all records, including police reports, medical records, witness statements, and photos you took of the scene. They may also revisit the scene of the accident or consult expert witnesses, such as medical experts or accident reconstruction specialists, to build the strongest possible case.

- Negotiation: Your lawyer will then get to work crafting a demand letter to the insurance company (or companies). One of the best things about hiring a personal injury attorney is that they handle all communications and negotiations with insurance companies on your behalf. Not only does this mean that you are less likely to fall victim to the insurance adjusters’ pressuring tactics, but it also allows you to focus more on what matters most: your recovery.

- Trial representation: While many personal injury cases end in settlements, sometimes both sides cannot come to an agreement for fair compensation. In these cases, your claim will proceed to trial, where it will be heard by a judge and/or jury. When a personal injury case goes to court, it is important to have a skilled trial lawyer on your side who is willing and able to argue your case.

How to determine which Virginia personal injury lawyer is best for your Virginia injury claim

However, it can be difficult to determine which personal injury attorney to hire. There are tons of radio ads, billboards, and Google search results that all claim to be the “best injury lawyer near me,” so how do you know which ones actually are the best? Attorney C. James Williams III, principal at Burnett & Williams, guides us through what injury victims should look for when hiring an attorney.

One of the first things to look for when hiring a personal injury attorney is their fee structure. The best personal injury lawyers typically work on a contingency fee basis, meaning they are paid a percentage of the final settlement or award. These are the “we don’t get paid unless you win” guarantees.

While other specialties, such as criminal law, operate on an hourly basis, the status quo for personal injury law is a contingency fee. “Be suspicious of anyone who asks for an upfront retainer or hourly rate for your personal injury case, as this could imply that they don’t think they can win your case,” Williams advises.

It is also important to look for a law firm with a specialty area that correlates with your specific accident. “Not every lawyer is trained and equipped to handle every personal injury case,” explains Williams. “For example, truck accidents involve additional complex laws beyond the typical auto accident case. So do motorcycle accidents. An attorney who has only ever handled standard car accident claims might not be the right fit to handle one of these cases.”

But perhaps the single biggest factor to consider when choosing the best injury lawyer near you is their track record. “More often than not, experienced personal injury attorneys’ results should be able to speak for themselves,” says Williams.

If a law firm has good reviews online and has a history of winning big settlements and jury awards, chances are they are a good choice to hire. “And as a bonus, the better the reputation, the more leverage you get in the negotiation process,” Williams adds. “Insurance companies are often scared to go to trial against a lawyer they think they might lose to.”

If you are looking for the best Virginia personal injury lawyers, look no further than the skilled and experienced attorneys at Burnett & Williams. “Contact us today for a free consultation,” concludes Williams. “We will review your case and determine if we can help get you the compensation you deserve.”

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle7 years ago

Lifestyle7 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment7 years ago

Entertainment7 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free