Lifestyle

From Disgruntled Consumer to Disruptive Inventor

They say “necessity is the mother of invention.” In Matthew Burwick’s case, the adage holds true.

Buwick’s creative process for developing Bob the Pillow was not enjoyable. Chronic pain coursing through his entire body and exhausting nights spent in poor sleep were the needs that prompted his transformation from consumer to inventor.

Spurring invention from a half-solved problem

When Burwick was six years old, a close neighbor was first to notice his limp. After extensive x-rays and several misdiagnoses, his family learned he had a condition called Legg Perthes disease.

Burwick spent six months in a full-body cast and emerged with a functional hip. Unfortunately, his legs were mismatched by about an inch in height. That minor discrepancy led to years of pounding on the joint.

“First, I felt knee pain,” recalls Burwick. “Heel and foot pain came next. Eventually, the pain spread to my shoulders, neck, and back. I was a 20-something trapped in a 90-year-old’s body.”

Burwick embarked on an orthopedic health journey, including heel lifts, chiropractor visits, low-intensity exercises, and various surgeons. At one point, his chiropractor mentioned the benefits of sleeping with a pillow between his legs.

After research, Burwick bought his first leg pillow. “I was thrilled to see my pain decrease,” he remembers, “but I wasn’t completely satisfied with that pillow. I tried another, then another, but each one fell short in some way from being the solution I needed.”

Turning the quest for a solution into a concrete product

Roughly 20 leg pillows later, Burwick remained convinced a solution was out there, but was unable to find it. A particularly rough week of sleep combined with the global lockdown was the perfect storm that transformed a frustrated consumer into a full-fledged entrepreneur.

“My latest pillow would not stay in place during the night,” Burwick remembers. “I woke up on my stomach at all hours. Every morning, I got out of bed in worse pain than the day before.”

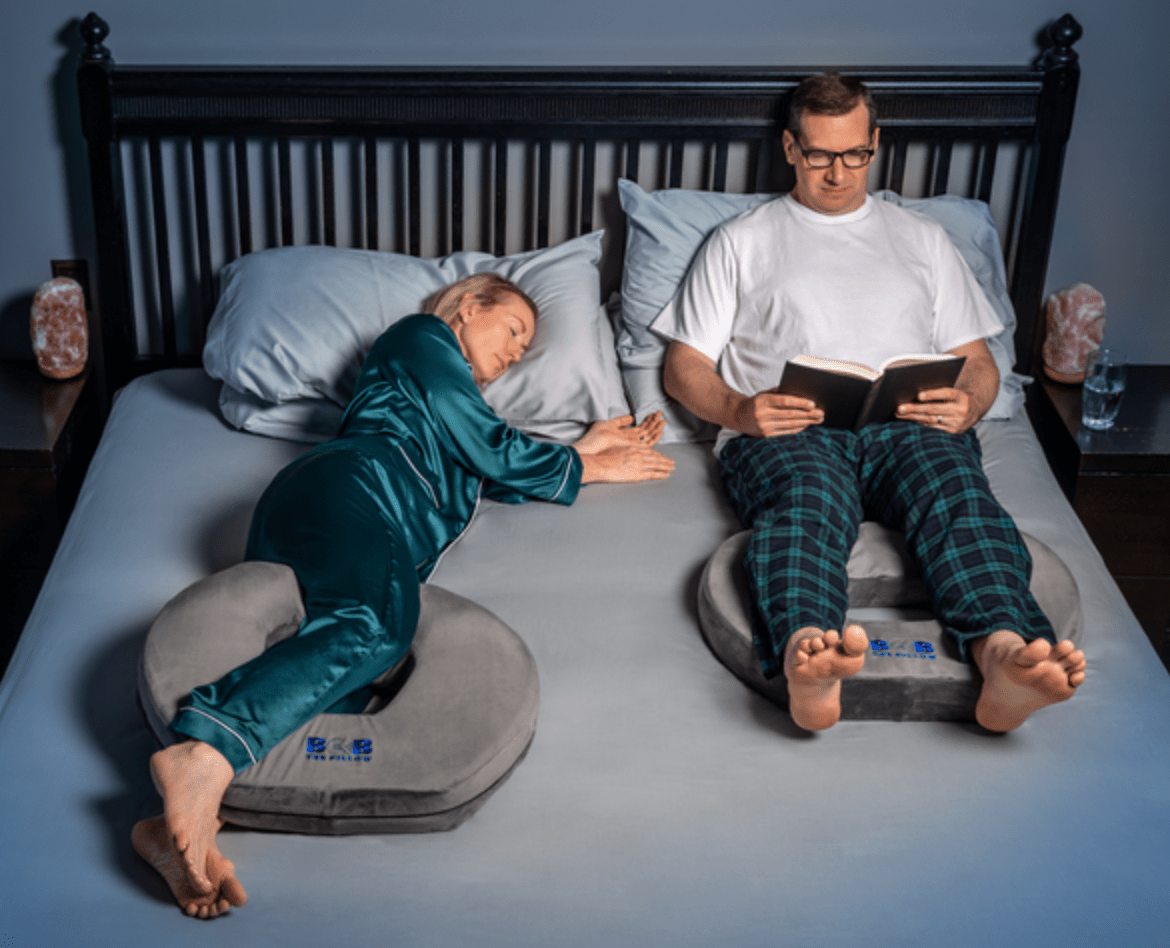

Burwick phoned his friend and future business partner and within hours, the pair was in a garage with furniture foam from a local fabric store and a hot glue gun. The first iterations of Bob the Pillow were laughable, but the goal was clear: make a pillow that would stay in place and keep people on their sides.

“We took pictures, sketched ideas, and found a CAD designer to bring our concept to life,” says Burwick. “Believe it or not, in under four months, we had a 3D-printed prototype for the inside of the pillow and sourced a seamstress in China capable of creating the complicated pillowcase. It wasn’t long before we had working samples.”

Understanding the process of invention

Aside from invention and product creation, innovation entails plowing through a mountain of mundane tasks. Burwick contacted a patent attorney, wrote a formal patent application, created a website, designed a logo, filed for trademarks, reviewed logistics companies, and established working relationships with importers who could ship Bob the Pillow from China to the warehouse. He coordinated all of these tiny tasks during a global pandemic and supply chain crisis.

“All of the jobs like design, legal, taxes, insurance, production, and shipping take an insane amount of time,” Burwick warns. “It’s easy to overlook details you find less exciting, but that is bound to bring trouble down the road.”

The final phase of invention involved spreading the word. Burwick chose to launch slowly and collect feedback as he went. “Strategic conversations with consumers early on gave us time to address customer input and make improvements as we grew,” he says. “Once you know there is a real need for the solution you are bringing to the market, all you have to do is educate yourself and push forward.”

Burwick’s motivation throughout the process of innovation and entrepreneurship sprang from a desire to get his pillow to people with chronic pain and sleepless nights. Today, he is thrilled every time he hears that a customer wakes up feeling better.

“Remember that just because a solution is available doesn’t mean the problem is solved,” Burwick advises. “Your idea may be just the solution for a problem that is only halfway solved. Our greatest joy is speaking to people who benefit from Bob the Pillow. My mission is to put our product into the hands of anyone dealing with long-lasting pain and give them the healing gift of sleep.”

Lifestyle

When the Body Speaks: How Maryna Bilousova Helps Clients Heal Beyond the Physical

Our bodies hold onto what our minds try to forget until they speak up through tension, fatigue, or illness. It’s easy to overlook signs like tight shoulders, restlessness, or headaches. But often, these signals are connected to something deeper. Maryna Bilousova has built her work around helping people listen to what their bodies are really saying.

Like many of her clients, Maryna spent years in a high-stress environment, constantly pushing through. She knew how to perform, meet goals, and keep everything running. But peace was missing. Her body carried the weight of unspoken stress. That realization changed not only her life, it shaped how she supports others today as a transformation coach and subconscious pattern specialist.

Instead of focusing only on what’s visible, Maryna helps people look inward. She works with individuals who feel stuck in cycles they can’t explain, like burnout that does not go away or stress that feels out of proportion. Often, the root is not just a busy schedule. It’s emotional tension that’s been buried and ignored.

Looking Deeper Than Symptoms

Many people come to Maryna after trying traditional methods. They have done meditation apps, therapy sessions, or self-help routines. Still, something feels off. That’s where her work begins, not with fixing, but with listening.

She helps clients connect the dots between their physical symptoms and unresolved emotions. It’s not always about big trauma. Sometimes, it’s small moments that were never processed, guilt, grief, frustration, or shame. Over time, those emotions settle in the body.

Maryna recalls one client, a long-term cancer survivor, who returned years later with ovarian cysts. The physical fear was real, but so was the emotional weight she had been carrying from a past relationship full of betrayal and silence. Through their sessions, they uncovered and released that emotional residue. Weeks later, the cysts were gone. It was a reminder of how deeply the body can reflect our inner state.

Patterns That Keep Us Stuck

Maryna’s approach is not about chasing positivity or trying to fix everything at once. She focuses on patterns, how people speak to themselves, how they respond to stress, how they make decisions. Often, what feels like self-sabotage is actually an old belief playing out.

For example, someone who always avoids conflict might be carrying a belief that their needs don’t matter. Another who keeps overworking may feel that slowing down means they are falling behind. These beliefs often form early and show up in adulthood in ways that quietly run our lives.

Rather than offering surface-level solutions, Maryna holds space for clients to explore what’s really behind their choices. Her calm presence allows people to soften, reflect, and begin making changes that come from clarity, not pressure.

A Path Back to Yourself

The people Maryna works with are not looking for a quick fix. They want to feel lighter, clearer, and more like themselves again. Her clients often say that what changes is not just their mindset, it’s how they feel in their own skin. They start resting without guilt, setting boundaries without apology, and making choices that actually feel good.

Maryna believes that healing is not about doing more. It’s about slowing down enough to notice what your body and mind have been trying to say all along. When people start listening, they stop feeling like they have to fight themselves, and that’s when real change happens.

In a world that pushes us to ignore discomfort and keep going, Maryna offers something different: a place to pause, reflect, and reconnect. Because sometimes, healing does not start with doing, it starts with listening.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle7 years ago

Lifestyle7 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment7 years ago

Entertainment7 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free