Lifestyle

Say Goodbye to Eyeliner Fails with TheGuideliner™

By: Mae Cornes

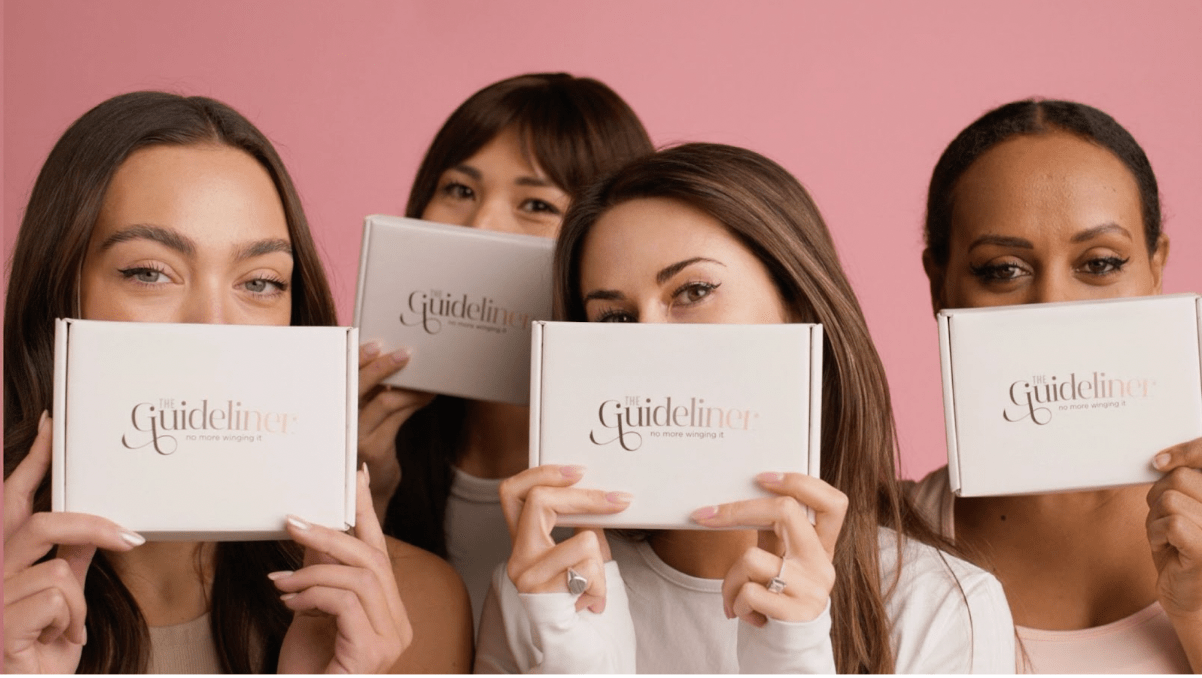

Good news is on the horizon for anyone who’s ever struggled to get their eyeliner just right. TheGuideliner™ is here to rescue makeup lovers from the dreaded uneven wings and smudged lines that have haunted them for years. With a fresh touch that blends practicality with eco-consciousness, TheGuideliner™ is shaking up the beauty scene and making winged eyeliner accessible to everyone—regardless of skill level.

Winged Eyeliner, Simplified

Let’s face it: winged eyeliner can be a real pain. It’s the ultimate makeup look, but achieving that perfect flick often feels like a game of chance. TheGuideliner™ promises to take the guesswork out of the equation with its innovative Peel, Press, and Seal method. Forget about shaky hands or the nerve-wracking symmetry check; this tool is designed to make the process foolproof.

The product features pre-shaped Guideliners™ infused with vegan, soy-based pigments. Users simply press them onto their eyelids, seal them with water and voilà! They have perfectly shaped wings in seconds.

It’s a simple yet brilliant solution that even makeup beginners can master. For seasoned pros, it’s a time-saving hack that makes sure flawless results every time.

“We wanted to create something that everyone could use, regardless of their experience with makeup,” says Charlie Pond, the mastermind behind TheGuideliner™. “It’s all about making beauty more accessible and enjoyable.”

Sustainable Makeup That Doesn’t Compromise

TheGuideliner™ isn’t just about creating the perfect look—it’s also about doing so responsibly. In an industry where sustainability is often more of a buzzword than a practice, this product sets itself apart by genuinely committing to eco-friendly beauty.

The company makes the Guideliners™ from 100% organic, vegan soy-based pigments. This offers a kinder alternative to traditional eyeliners, which often rely on harsher chemicals and materials.

The company extends its commitment to sustainable makeup to the packaging as well. TheGuideliner™ uses recyclable and compostable materials, so customers can feel good about reducing their environmental footprint with each purchase. It’s a win-win: users get a high-quality, innovative product while supporting a brand that cares about the planet.

Inclusive Beauty Solutions for Everyone

One of the standout features of TheGuideliner™ is its emphasis on inclusivity. Beauty should be fun and accessible, and this solution guarantees that everyone, regardless of their abilities or makeup proficiency, can enjoy the process.

Individuals with motor skill challenges have praised the product notably. There are many people around the world that find traditional eyeliner application challenging. TheGuideliner™’s simple application method levels the playing field, allowing everyone to achieve the same flawless results.

But the brand doesn’t stop at inclusivity in usability. TheGuideliner™ also offers a variety of sizes and colors to suit different styles and preferences, from subtle and chic to bold and dramatic. Whether someone is looking to make a statement or just wants a little everyday glam, TheGuideliner™ has them covered.

What Consumers Are Saying

TheGuideliner™ launched in April 2024, and it’s already making waves in the beauty e-commerce space. The product has quickly attracted a loyal following, with glowing reviews from Australia, New Zealand, and the U.S.—key markets where the demand for sustainable and innovative beauty solutions is rising.

According to industry reports, the beauty e-commerce market in these regions is expected to grow significantly in the coming years. Forecasts predict a CAGR of 8-10% in Australia and New Zealand and 6-8% in the U.S. between 2024 and 2025.

Without a massive advertising push, TheGuideliner™ has relied on word of mouth and social media buzz to drive its growth. Users are not just buying the product—they’re raving about it.

People highlight how it simplifies their beauty routine and offers a reliable, long-lasting solution to the eyeliner woes they’ve faced for years. The product’s ability to stay put for up to three days without smudging or fading is a game-changer for many, making it a staple in their beauty arsenal.

What’s Next for TheGuideliner™

While TheGuideliner™ is off to an impressive start, the brand isn’t resting on its laurels. The beauty industry is competitive, and staying ahead means continually innovating. The company plans to expand its product line to include even more styles and colors, catering to a broader range of tastes and preferences.

Expanding into new markets is also on the horizon. With its commitment to eco-friendly beauty and inclusivity, TheGuideliner™ is well-positioned to impact regions increasingly prioritizing these values. The U.S., Australia, and New Zealand remain key areas of focus, where the brand will continue to build its presence and offer sustainable, inclusive beauty solutions.

“We’re excited about what the future holds,” says Pond. “Our focus will always be on listening to our customers and evolving our products to meet their needs. Everyone deserves to feel confident in their makeup, and we’re here to make that happen.”

Lifestyle

When the Body Speaks: How Maryna Bilousova Helps Clients Heal Beyond the Physical

Our bodies hold onto what our minds try to forget until they speak up through tension, fatigue, or illness. It’s easy to overlook signs like tight shoulders, restlessness, or headaches. But often, these signals are connected to something deeper. Maryna Bilousova has built her work around helping people listen to what their bodies are really saying.

Like many of her clients, Maryna spent years in a high-stress environment, constantly pushing through. She knew how to perform, meet goals, and keep everything running. But peace was missing. Her body carried the weight of unspoken stress. That realization changed not only her life, it shaped how she supports others today as a transformation coach and subconscious pattern specialist.

Instead of focusing only on what’s visible, Maryna helps people look inward. She works with individuals who feel stuck in cycles they can’t explain, like burnout that does not go away or stress that feels out of proportion. Often, the root is not just a busy schedule. It’s emotional tension that’s been buried and ignored.

Looking Deeper Than Symptoms

Many people come to Maryna after trying traditional methods. They have done meditation apps, therapy sessions, or self-help routines. Still, something feels off. That’s where her work begins, not with fixing, but with listening.

She helps clients connect the dots between their physical symptoms and unresolved emotions. It’s not always about big trauma. Sometimes, it’s small moments that were never processed, guilt, grief, frustration, or shame. Over time, those emotions settle in the body.

Maryna recalls one client, a long-term cancer survivor, who returned years later with ovarian cysts. The physical fear was real, but so was the emotional weight she had been carrying from a past relationship full of betrayal and silence. Through their sessions, they uncovered and released that emotional residue. Weeks later, the cysts were gone. It was a reminder of how deeply the body can reflect our inner state.

Patterns That Keep Us Stuck

Maryna’s approach is not about chasing positivity or trying to fix everything at once. She focuses on patterns, how people speak to themselves, how they respond to stress, how they make decisions. Often, what feels like self-sabotage is actually an old belief playing out.

For example, someone who always avoids conflict might be carrying a belief that their needs don’t matter. Another who keeps overworking may feel that slowing down means they are falling behind. These beliefs often form early and show up in adulthood in ways that quietly run our lives.

Rather than offering surface-level solutions, Maryna holds space for clients to explore what’s really behind their choices. Her calm presence allows people to soften, reflect, and begin making changes that come from clarity, not pressure.

A Path Back to Yourself

The people Maryna works with are not looking for a quick fix. They want to feel lighter, clearer, and more like themselves again. Her clients often say that what changes is not just their mindset, it’s how they feel in their own skin. They start resting without guilt, setting boundaries without apology, and making choices that actually feel good.

Maryna believes that healing is not about doing more. It’s about slowing down enough to notice what your body and mind have been trying to say all along. When people start listening, they stop feeling like they have to fight themselves, and that’s when real change happens.

In a world that pushes us to ignore discomfort and keep going, Maryna offers something different: a place to pause, reflect, and reconnect. Because sometimes, healing does not start with doing, it starts with listening.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle7 years ago

Lifestyle7 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment7 years ago

Entertainment7 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free