Lifestyle

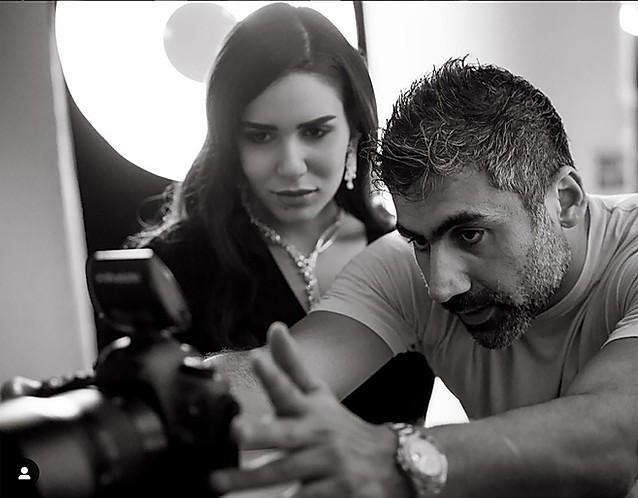

The medium does not matter if you are truly artistic, says renowned photographer Hikmat Wehbi

Artists have the unique ability to utilize many different types of mediums to create and inspire audiences worldwide. While many artists might be famous for the use of a particular medium, the truth is they have all experimented with different kinds throughout their careers. Being a successful artist is all about taking risks, and renowned photographer Hikmat Wehbi built his career on a combination of talent and exceptional use of mixed media.

Hikmat Wehbi is a world-famous photographer currently living in Dubai. Originally from Beirut, he is the founder of W Studio, a creative director and director of photography. Hikmat started his business focused on fashion and portraits but quickly adapted to a changing marketplace due to his keen eye for creativity and his ability to embrace it. “Photography is all about maximizing the beauty of a moment, and you have to be willing to experiment,” says Hikmat. “Experimentation is at the root of all artistic talent.”

What sets Hikmat apart is his ability to see potential in all types of mediums. Hikmat doesn’t like to confine himself to one approach as he feels that it can limit an artist and hinder their talent. As W Studio rose to prominence in Dubai, Hikmat found himself experimenting with media to meet a more diverse range of clients. Shifting his focus changed the studio for the better. It evolved from a portrait studio to a full-fledged production company catering to all kinds of clients spanning advertising to hospitality, delivering digital and social media content.

“If you are truly artistic, the medium doesn’t matter,” explains Hikmat. “You will see the potential and deliver on it. That is what an artist does. A true artist is never limited by medium. They only work harder when presented with something new.” With over twenty years of experience, Hikmat is now a trusted production artist for brands like Chanel, L’Oreal, Dior, Carolina Herrera, and many others.

To Hikmat medium is all about utilizing the various tools artists have at their disposal, and exceptional artists know that their work relies on using all these tools fearlessly and appropriately. “With the rise of digital media, there is so much pressure on artists to push the envelope, but I welcome it as a challenge to push my abilities,” says Hikmat. With the ever-changing media landscape, Hikmat Wehbi is undoubtedly leading the charge for all artists to embrace it.

Lifestyle

The Breakroom Reset: Small Changes That Improve the Workday

The office breakroom is a space that’s often neglected and can sometimes feel more like an afterthought than a key feature of the workplace. This is unfortunate, especially since employees typically visit the breakroom to rest and recuperate before finishing their shift. Considering its intended function, the breakroom should be viewed as one of the most important spaces in the entire office.

Having a welcoming and rejuvenating breakroom can promote social interaction, enhance workplace culture, and reduce stress. Employees who feel restored after visiting the breakroom are more likely to feel happy at work and be more productive the rest of the day. If your workplace breakroom leaves a lot to be desired, here are some small changes you can make to totally reset it.

Small Breakroom Changes That Improve the Workday

Unless your breakroom is in shambles and needs major reconstruction, you don’t have to spend a fortune on it to make it more inviting. In many cases, small and simple changes can make a big impact on the overall vibe of any space.

Whether you’re working with a limited budget or limited space, there are still plenty of things you can do to reset your boring breakroom. Here are some small breakroom changes that can improve the workday and give you maximum bang for your buck.

Convenient Hydration Options

Employees need to stay hydrated to keep their health and energy levels high. Unfortunately, many employees are chronically dehydrated because they don’t have access to tasty beverages at work. This doesn’t necessarily mean you have to install a soda machine in the breakroom. Giving workers unlimited access to sugary drinks could backfire in the long run by contributing to illnesses and increased sick days.

Instead of offering sugary beverages (that can actually contribute to dehydration in the long run), make it easier for your employees to stay hydrated with pure water. Providing a filtered office drinking water system is one of the best ways to encourage optimal hydration. Most employees will appreciate the clean, tasty alternative to standard office tap water.

Comfy Seating

When was the last time you took a look at the seating arrangements in your breakroom? If it’s been a while, take a walk over there and give it a good look. Is there sufficient space for multiple employees to sit at the same time? Are the seats comfortable and rearrangeable so employees can interact with others or achieve greater privacy as desired? If not, you might benefit from a breakroom seating reset.

Seating arrangements in breakrooms should be both comfortable and flexible. You might want to bring in some modular furniture because it’s easy to move and rearrange as needed. For maximum versatility, seating arrangements should include a mix of traditional breakroom chairs and tables, lounge chairs, and even bean bags. Making the space as open as possible will also help it look more roomy and inviting.

Nutritious Snack Options

Most employers don’t provide full meals for their employees. It’s perfectly reasonable to expect workers to make their own lunch or dinner arrangements. However, if you want to support your employees’ energy levels, keep healthy snacks in your breakroom. Nutritious snacks can enhance employee performance throughout the day, so workers find it easier to get more done.

Instead of investing in chips, candy bars, and other sugary sweets, opt for snack options that won’t cause sugar spikes and inevitable crashes. Some great options include trail mixes, protein bars, fresh fruit, popcorn, and veggie trays. Instant oatmeal cups can also be a convenient source of energy for those who don’t have time to grab breakfast before heading to work. You might want to send out an employee survey to see what types of healthy snacks your workers prefer.

Optimal Lighting

Did you know that poor lighting can negatively impact your employees’ psychological and emotional well-being? Improving workplace lighting (including in the breakroom) can make a huge difference in worker morale and energy levels. Warm white light may be a great choice for the breakroom because it creates a soothing, calm atmosphere. Cool white light might be a better fit for conference rooms and cubicle areas because it enhances focus and energy.

Of course, natural light is arguably the best option for the office whenever it’s available. If your breakroom has windows, try to keep the shades open during working hours. That way, employees can experience the mood- and health-boosting benefits of natural light exposure.

Entertainment Options

Some office managers and CEOs mistakenly think that a breakroom should be boring to serve its purpose well. However, the terms “boring” and “relaxing” are not synonymous. Employees may find a boring breakroom to be surprisingly non-restorative. On the flip side, a room equipped for entertainment can be very relaxing and rejuvenating.

To make your breakroom a more enjoyable place to spend time, you might want to install a corner television. That way, workers can watch their favorite sitcom while they relax. You might also keep a few card or board games stocked in a cupboard for employees who prefer to interact in fun ways during their lunch breaks.

Reset Your Breakroom Today

Your employee breakroom can reveal a lot about your overall workplace environment. If it’s not lit well, or if it’s boring and unwelcoming, workers are more likely to feel underappreciated and discontented. The good news is that you don’t have to sink a lot of money or effort into resetting your breakroom and getting a fresh start. Use these simple tips to revamp your breakroom and make it a place where workers can go to feel truly cared for and relaxed.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle7 years ago

Lifestyle7 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment7 years ago

Entertainment7 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free