Tech

Most Noteworthy Advantages to Using Plastic Injection Molding for the Manufacturing of Parts

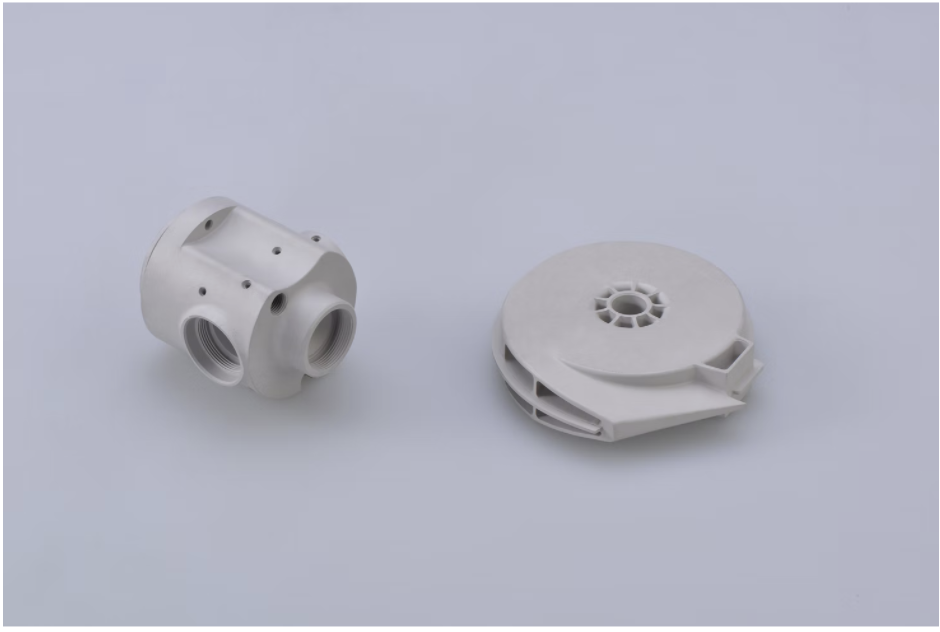

Injection molding is a manufacturing process that involves the production of parts by injecting molten material into a mold. This production method is popularly used in mass-production processes where the same part is made thousands of times in succession. How is it done? The mold is customized during tooling, which gives the shape of the part. As a result, it can create numerous identical and dimensionally consistent pieces, even on parts with complex designs.

When used to mass fabricate plastic parts, the process is known as plastic injection molding. In this case, the process involves an injection of molten plastic material into the mold, which cools and solidifies to its final form. Plastic injection molding is ideal for manufacturing high volumes of plastic products, which serves many industries and individuals.

Parts and products produced with this method are, for example, bottle caps, automotive parts and components, toys, one-piece chairs and small tables, mechanical parts, and many other plastic products.

But let’s take a closer look at the advantages of this type of production.

#1 Ability to produce detailed and complex parts with high precision

Injection molding is excellent for manufacturing highly complex and detailed plastic parts in large volumes with nearly no deviation. That is because it easily integrates with computer-aided design. Hence, it relies on comprehensive data collection and analysis techniques at the center of scientific molding and the engineers trained in the process.

Furthermore, plastic injection molding allows you to incorporate more features at minimal tolerances than other methods. Injection molders can complete designs accurately to within +/- .001 inches. These measurements are possible and are also repeatable across production runs and equipment.

#2 Efficiency and speed

Injection molding has a high production output rate, is cost-effective, and fast, making it the most efficient form of molding. Cycle times during this process that can be as low as 10 seconds, combined with the high quality of molds, mean a lot of products within a limited time frame.

That implies that this method generates excellent profit margins. In addition, implementing techniques like greater upfront focus on design to minimize problems later on and incorporating value-added services to combine production process steps can streamline time and cost burdens.

#3 Strenght and stability

Today’s lightweight thermoplastics can resist even the harshest conditions, and for constructing complex injection-molded applications, there are many engineered materials to choose from. Furthermore, the plastic injection molding process uses filters to reduce the density of plastic that adds strength and stability to the molded part.

High-performance blends and hybrids can also be formulated to meet particular part requirements and characteristics. Naturally, a proper balance of design considerations and material selection, based on the set conditions for the end product, helps additionally address the need for strength and stability.

#4 High-output production and consistency

High-output production of complex plastic parts demands a consistent, repeatable process to achieve designs with tight tolerances. Injection molding can produce numerous identical parts with consistent form and dimensions because it repeatedly uses the same mold for each piece. This advantage is essential when product consistency and part reliability in high volume production is required.

#5 Great flexibility

Injection molding offers excellent flexibility:

- There are many materials nowadays in polymers, as there are many plastic resins. Moreover, injection molding can simultaneously use multiple types of plastics.

- It allows for custom color choices thanks to the multiple coloring techniques that are available for adding shades the plastics,

- With plastic injection molding processes, multiple finish appearances like smooth surface finish, matte, or even unique textures.

- Can meet specific project requirements.

#6 Waste reduction

Plastic pollution worldwide has gone up to a severe level. As a result, industrial manufacturing processes must secure that they go hand in hand with today’s environmental considerations. In this direction, plastic injection molding uses only the required plastics during the production process and does not leave substantial waste. Hence it produces much less waste than traditional techniques, such as, for example, the conventional machines that cut plastic pieces from larger blocks.

#7 Lower labor costs

The ability to produce parts in bulk with minimal time and high output ratio makes injection molding a highly efficient process in terms of cost. In addition, the molding equipment requires minimal supervision because the process is entirely automated, so it streamlines labor costs and dramatically reduces the risk of rework caused by part defects or human error, ultimately saving money.

Conclusion

To truly benefit plastic injection molding, manufacturers must look for quality materials and experienced custom injection molders that know how to maximize efficiency and overcome any design or process issues. Having the best equipment, materials, and know-how ultimately makes a difference in the costs and final quality.

Tech

My Main AI Turns Complex Workflows into Simple, Voice-Driven Conversations

By: Chelsie Carvajal

Managing modern workflows often means juggling dashboards, documents, and long email threads before a single task is complete. My Main AI Inc, an AI technology platform that spans text, image, voice, and video, has built a system where many of those steps can be handled through spoken or written prompts instead of manual clicks.

Turning Tasks Into Conversations

My Main AI groups several automation tools around a voice and chat layer so users can move through work by giving instructions rather than configuring each step. The platform lists AI Web Chat, AI Realtime Voice Chat, AI Speech‑to‑Text Pro, and AI Text‑to‑Speech engines from providers such as Lemonfox, Speechify, and IBM Watson, creating a loop between spoken input and generated output.

Speech‑to‑text tools support accurate transcription of audio content in multiple languages, with options to translate those recordings into English. That capability gives businesses a way to record meetings, calls, or field conversations, then convert the results into text that can be summarized, edited, and turned into documents or scripts. Text‑to‑speech tools, including multi‑voice synthesis with up to 20 voices and SSML controls, take written content in the other direction, producing voiceovers for training, marketing, and support material.

Chat assistants extend the same pattern to files and websites. My Main AI lists AI Chat PDF, AI Chat CSV, and AI Web Chat, which allow users to ask questions of documents or site content through natural language prompts. Instead of sorting through long reports, a user can query a file, receive concise answers, and then send follow‑up requests to generate emails, briefs, or summaries in the same environment.

From Content Pipelines to Voice‑Led Workflows

The company reports that its platform connects to more than 100 models from OpenAI, Anthropic, Google Gemini, xAI, Amazon Bedrock and Nova, Perplexity, DeepSeek, Flux, Nano Banana, Google Veo, and Stable Diffusion 3.5 Flash. Public materials state that these models support text, image, voice, and video generation in more than 53 languages, giving the voice‑driven tools reach across several regions and markets.

Content creation sits at the center of many of these workflows. My Main AI offers modules for blog posts, email campaigns, ad copy, social captions, video scripts, and structured frameworks such as AIDA, PAS, BAB, and PPPP. A user can dictate key points or paste a brief into the chat, receive draft text, ask the assistant to adjust tone or length, and then pass the result into voice synthesis to create a narrated version.

Visual tools fit into the same flow. DALL·E 3 HD, Stable Image Ultra, and an AI Photo Studio support image creation, product mock‑ups, background changes, and multiple variations from a single upload. AI Image to Video and text‑to‑video connections with engines such as Sora and Google Veo, alongside an AI Avatar feature labeled “coming soon,” make it possible to turn a spoken or typed brief into images, then into short clips that accompany the newly generated audio.

Why Businesses See Conversation as Infrastructure

Company data shared with partners cites more than 77,000 customers worldwide, annual revenue near 3 million dollars, and monthly revenue growth around 250,000 dollars, driven largely by subscription sales. The 49‑dollar plan is described as the best‑selling tier, with My Main AI presenting it as the entry point to the broader suite of conversational and automation tools.

Business‑oriented features show how these voice‑driven workflows connect to operations. The platform lists payment gateways such as AWDpay and Coinremitter, integrations with Stripe, Xero, HubSpot, and Mailchimp, and tools for SEO, finance analytics, dynamic pricing, wallet systems, and referrals. A manager can ask a chat assistant to pull figures, draft a report, and prepare customer messages, then move directly into sending campaigns or reviewing payments through linked services.

Company communications describe ongoing work on proprietary models, expanded training flows from text, PDFs, and URLs, and deeper tools for chat, analytics, and video. That roadmap suggests that My Main AI views conversation—spoken or typed—as a central control surface for complex workflows, with automation stepping in behind the scenes so users can focus on clear instructions rather than manual configuration.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle7 years ago

Lifestyle7 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment7 years ago

Entertainment7 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free