Lifestyle

Sterling Silver Jewelry is more Popular now than ever Before

Sterling silver has a timeless appeal and durability and has become the metal of choice for modern jewelry. Manufacturers of exceptional jewelry pieces around the world have dispelled the myths around silver and have proven that it has the right malleability, beauty and durability to create trendy and exquisite marcasite pieces to be enjoyed by women globally.

Dispelling of a myth

For some people, fine jewelry can only be made of pure gold, but for most sterling silver has connotations of luxury which are found in the old English expression “born with a silver spoon in the mouth”.

Sterling silver is made with 92.5% silver and 7.5% other metal alloys and may be slightly cheaper than white gold, but makes an excellent substitute for many types of jewelry pieces.

These are the some of the reasons why most women (and men) prefer to have sterling silver in their jewelry box:

Durability

Sterling silver is far pricier than some artificial substitutes but it lasts a lifetime, even becoming family heirlooms. The best quality silver jewelry is made by reputable companies and will carry the sterling silver stamp on a hidden place on the item so that you can know its quality.

Trendy

Silver jewelry is almost always popular and with a few good pieces in your collection you can know that you will always have something trendy to wear. As a metal, silver is relatively soft and can be molded into various styles. Many people seem to think that silver is only suitable for earrings. There are literally thousands of options for designs that vary from the modern to antique looking. Silver can be set with stones, pearls and turned into lockets, bracelets, rings, pendants, and watches.

Exciting designs

Jewelry designers have a preference for working silver designs and that is why there is such a proliferation of beautiful pieces available for woman to build onto their jewelry collections. Silver collections can add class to any type of outfit and they can be matched with white gold or platinum pieces.

It can be worn by everyone

Silver jewelry designs have adapted to the needs of men who also prefer to wear rings, bracelets and necklaces made with silver.

Silver is nickel and lead free

For many women today, allergies to some base metals does not allow them to wear most of the inexpensive jewelry available. Nickel and lead can irritate the skin and cause allergic reactions. Besides pierced ears, more people today enjoy wearing piercings elsewhere. Both men and women can know that silver is the best choice for their piercings.

If you have ever worn a cheap pair of earrings and have felt sore after about an hour, this is because of a reaction to the metals used. Silver is a metal that hardly ever causes any reactions. Most silver jewelry has a copper alloy which is also highly unlikely to cause a reaction, and silver jewelry can be worn without worry.

Maintenance of silver jewelry

If not worn often, silver jewelry may tarnish, but that is not permanent and can be cleaned in a few simple steps. The more you wear your silver jewelry, the better as the oils from the skin help to keep the metal clean and shiny.

Restore the original shine of your silver with a silver cleaner and soft cloth which can be bought from most jewelers and grocery stores.

Affordability

All silver jewelry is an affordable investment that allows moment to build up an extensive jewelry box of beautiful pieces to alternate for any occasion without breaking the bank.

Silver and global demand

Mexico is still the leading producer of silver, followed by China and Peru. Besides its use for jewelry and coins, silver has other applications in electronics, printed circuits, dentistry and even photography.

The manufacture and exports of wholesale silver jewelry is an ever-growing industry. Thailand has overtaken India in silver jewelry exports, and Thailand’s leading jewelry manufacturer is Hong Factory, started in 1971. The family owned business designs and crafts exquisite original pieces that are exported to over 60 countries globally and are known for their scrupulous attention to the finest details.

According to Mr. Hong, a leader in wholesale silver jewelry in Thailand, “Our factory has served thousands of jewelers with wholesale silver and marcasite jewelry collection and the advanced OEM & ODM jewelry. We plan to continue offering our wholesale clients and their customers the same excellence of service with our excellent quality and designs.”

Today’s leading jewelry manufacturers know that they need to meet the demand of their discerning clients with cutting edge techonology, while also keeping up with the highest standards of sustainability and ethics demanded by the consumers of their products.

Lifestyle

How Magic Moment Resort Became the Pioneer of a New Era: The First-Ever Dazzler Select by Wyndham

In Central Florida’s packed landscape of family hotels and theme park lodgings, a unique kind of property has emerged. Magic Moment Resort & Kids Club in Orlando is earning attention from traveling families for a simple reason. It delivers joy, warmth, and convenience at a smart value that keeps Disney dreams accessible rather than overwhelming.

By joining Wyndham, Magic Moment Resort unlocks the strength of a global powerhouse, gaining worldwide visibility, advanced technology, and access to Wyndham Rewards, the largest hotel loyalty program on the planet. This strategic move expands its reach, builds guest trust, and amplifies its impact, all while preserving the unique identity that sets it apart.

Just a short drive from the gates of Walt Disney World, the resort sits along the palm-framed stretch of West Irlo Bronson Memorial Highway. The location has long been known for its tourism bustle, yet Magic Moment has carved out a softer identity. It feels playful and colorful, but also intentional. It is designed by a family for other families, and that perspective shapes every experience on the property.

A Philosophy Rooted in Family Connection

Magic Moment Resort was built with a belief often forgotten in today’s tourism industry. Family vacations should feel uplifting instead of stressful, and affordability should not come at the expense of comfort or creativity.

Check-in feels more personal than transactional. Parents arrive with strollers, snacks, and tired children. The staff seems to understand this rhythm instinctively. The energy is warm, the pace is easy, and the tone is set long before anyone even enters the room.

Unlike competing hotels that charge a steep premium for proximity to the parks, Magic Moment focuses on smart value without compromise. Its pricing strategy is refreshingly straightforward. Families can stay five minutes from Disney without draining their travel budgets. For many guests, that difference helps shift resources from hotel costs to experiences. It means more character breakfasts, more souvenirs, and more freedom to enjoy the parks without financial tension following every decision.

Spaces Designed for Children and Considerate of Parents

Magic Moment is filled with color, but nothing feels overstimulating. Instead, the resort offers a sense of wonder scaled to a child’s imagination.

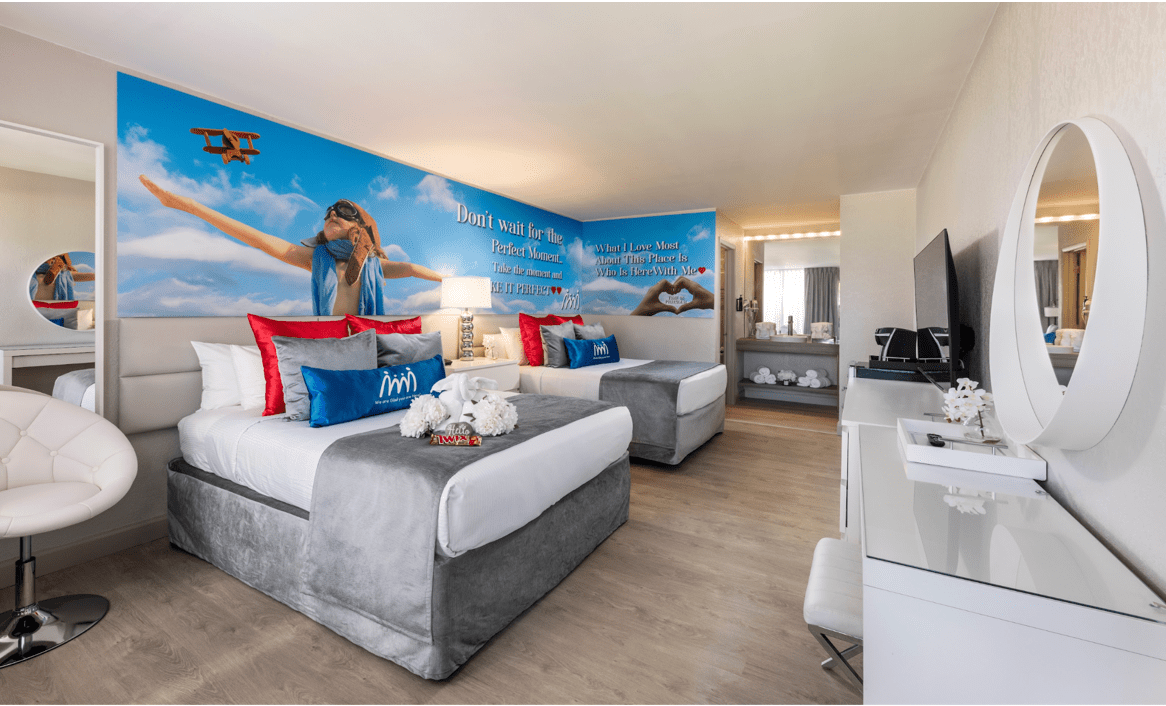

The themed family rooms are a highlight. Children step into rooms that feel lighthearted and whimsical, yet parents appreciate that they are also functional and comfortable. It is the atmosphere of a themed suite without the theme park price.

Its Kids Club and Teens Club reflect that same thoughtful balance. These spaces invite exploration and creativity for children and provide a nurturing level of supervision. Parents can enjoy an hour by the heated pool, relax in a shaded cabana, or simply take a quiet moment while knowing their children are safe and engaged.

The resort’s grounds encourage slow mornings and gentle afternoons.There’s a 30,000 sqf outdoor playground as well as peaceful corners for parents. Importantly, families are not asked to pay additional fees to enjoy them. Magic Moment’s amenities feel generous rather than transactional.

Unforgettable Days at the Parks

For families navigating a Disney vacation, convenience is often the true luxury. Magic Moment delivers this with a complimentary delicious hot breakfast that encourages everyone to sit and enjoy the start of the day rather than rush through it.

Transportation to the parks is included, which removes one of the most common stress points for visiting families. There is no parking lot maze and no long lines at the toll booths. Guests simply board the shuttle and begin their day with ease.

When the sun sets and everyone returns from a day of rides and parades, the resort becomes a place to unwind. Children head straight for the pool. Parents sip Starbucks coffee. The atmosphere is relaxed and bright, and the resort feels like an extension of the Disney experience rather than a pause from it.

A Value That Resonates with Families

What truly elevates Magic Moment is the balance it achieves between smart value and experience. The resort has cultivated a loyal following because guests feel they receive more than they pay for. More thoughtful design. More space for connection. More comfort without excess.

Affordability here does not signal minimalism. Instead, it allows families to breathe. It creates space for shared moments that are often overlooked in the rush of theme-park vacations. Children play freely. Parents unwind without guilt. Families spend more time together and less time navigating logistics.

A Resort Built with Heart

Magic Moment Resort & Kids Club stands out in a region overflowing with hospitality options. Its charm is not rooted in extravagance. It is grounded in sincerity. It reflects the belief that family travel should feel joyful, accessible, and full of color.

For families planning a Disney visit, it represents more than a place to sleep. It is a retreat where memories can form in the quiet moments as much as in the thrilling ones.

At Magic Moment, the greatest luxury is not an amenity. It is the feeling of being exactly where you are meant to be, together.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle6 years ago

Lifestyle6 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment6 years ago

Entertainment6 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free