Lifestyle

Beautiful Hard Work: Drilleys Eco Bags on Miss Korea Competition

Beyonce taught us all in “Pretty Hurts” that beauty isn’t all it’s cracked up to be. “Miss Congeniality” made us laugh, but also made us think about beauty pageants in a different way. More and more contestants are using the competition to speak about social issues.

From all these things and more, we now understand that being a Beauty Queen is hard work. That’s why we’re sure that the contestants in the Miss Korea competition were particularly pleased with one of the gifts they received. Each of the final contenders received a Drilley’s Earth Eco Bag, a hard-working, heavy duty tote that’s nonetheless quite fashionable.

Often, this kind of heavy-duty tote bag isn’t very stylish. You’ll find them in grocery stores, often plastered with logos or photos of trees. They’re fantastic for shopping, but not something you’d want to carry if you were trying to look cool.

Drilley’s bags are an exception to this. It is just as strong or more as any reusable grocery bag and at least ten times more fashionable.

Hardworking Bags for Busy Lives

Even though we’ve all seen the documentaries and the movies, it’s probably impossible to imagine what it’s like to compete in an international level beauty pageant unless you’ve actually done so.

The women on Miss Korea 2018 no doubt have busy, hectic lives and the preparation for the competition must be intense. Before, during, and after the show, they must need to carry loads of things with them, from makeup to wardrobe and beyond.

The great thing about Drilley’s eco totes is that they can carry extra loads. The brand uses industrial grade canvas, which is several times stronger than normal canvas. The Earth Eco Bag, the model that each contestant received, is a large shoulder-type bag with long handles that make it easy to carry. If you needed, you could really pack it. You’d only have to worry about carrying it yourself, not it breaking!

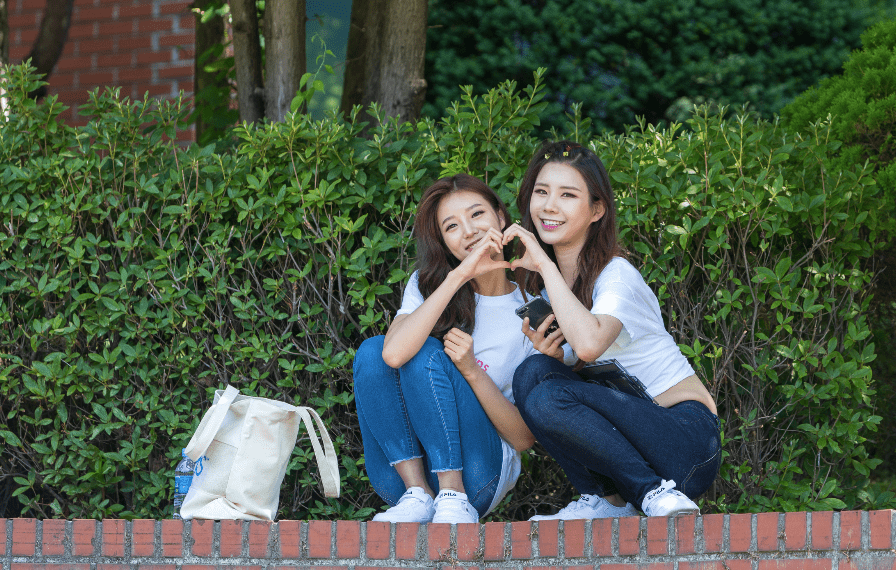

Still, once the cameras are rolling, nobody wants to see someone struggling with a huge bag full of stuff. And yet, they’d certainly need to bring some things along for the various outings, appearances, endorsements, and other requirements of the show. Why bother taking a new bag, though, when you have a Drilley’s?

The natural cream canvas shines through in the bags, complemented by Drilley’s looping logo in a variety of colors. It’s casual, fun, and yet still sophisticated. It doesn’t look out of place at all with these very fashionable women, and that’s definitely saying something for “just” an eco tote!

This original color is bright and warm, however, if you’re looking for something more somber, Drilley’s does offer a few darker colors.

What they all share is the same toughness. It’s scuff resistant and water resistant, which means that these bags really can take anything you throw at them. Much like, we imagine, the tough and beautiful women competing on the Miss Korea competition.

Find out more and order your own bag just like these beauty queens at www.drilleys.com!

Lifestyle

When the Body Speaks: How Maryna Bilousova Helps Clients Heal Beyond the Physical

Our bodies hold onto what our minds try to forget until they speak up through tension, fatigue, or illness. It’s easy to overlook signs like tight shoulders, restlessness, or headaches. But often, these signals are connected to something deeper. Maryna Bilousova has built her work around helping people listen to what their bodies are really saying.

Like many of her clients, Maryna spent years in a high-stress environment, constantly pushing through. She knew how to perform, meet goals, and keep everything running. But peace was missing. Her body carried the weight of unspoken stress. That realization changed not only her life, it shaped how she supports others today as a transformation coach and subconscious pattern specialist.

Instead of focusing only on what’s visible, Maryna helps people look inward. She works with individuals who feel stuck in cycles they can’t explain, like burnout that does not go away or stress that feels out of proportion. Often, the root is not just a busy schedule. It’s emotional tension that’s been buried and ignored.

Looking Deeper Than Symptoms

Many people come to Maryna after trying traditional methods. They have done meditation apps, therapy sessions, or self-help routines. Still, something feels off. That’s where her work begins, not with fixing, but with listening.

She helps clients connect the dots between their physical symptoms and unresolved emotions. It’s not always about big trauma. Sometimes, it’s small moments that were never processed, guilt, grief, frustration, or shame. Over time, those emotions settle in the body.

Maryna recalls one client, a long-term cancer survivor, who returned years later with ovarian cysts. The physical fear was real, but so was the emotional weight she had been carrying from a past relationship full of betrayal and silence. Through their sessions, they uncovered and released that emotional residue. Weeks later, the cysts were gone. It was a reminder of how deeply the body can reflect our inner state.

Patterns That Keep Us Stuck

Maryna’s approach is not about chasing positivity or trying to fix everything at once. She focuses on patterns, how people speak to themselves, how they respond to stress, how they make decisions. Often, what feels like self-sabotage is actually an old belief playing out.

For example, someone who always avoids conflict might be carrying a belief that their needs don’t matter. Another who keeps overworking may feel that slowing down means they are falling behind. These beliefs often form early and show up in adulthood in ways that quietly run our lives.

Rather than offering surface-level solutions, Maryna holds space for clients to explore what’s really behind their choices. Her calm presence allows people to soften, reflect, and begin making changes that come from clarity, not pressure.

A Path Back to Yourself

The people Maryna works with are not looking for a quick fix. They want to feel lighter, clearer, and more like themselves again. Her clients often say that what changes is not just their mindset, it’s how they feel in their own skin. They start resting without guilt, setting boundaries without apology, and making choices that actually feel good.

Maryna believes that healing is not about doing more. It’s about slowing down enough to notice what your body and mind have been trying to say all along. When people start listening, they stop feeling like they have to fight themselves, and that’s when real change happens.

In a world that pushes us to ignore discomfort and keep going, Maryna offers something different: a place to pause, reflect, and reconnect. Because sometimes, healing does not start with doing, it starts with listening.

-

Tech5 years ago

Tech5 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle7 years ago

Lifestyle7 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle5 years ago

Lifestyle5 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health7 years ago

Health7 years agoCBDistillery Review: Is it a scam?

-

Entertainment7 years ago

Entertainment7 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free