Tech

Everything About Non-Thermal Cutting Technology

Thermal Cutting is a family of processes in which heat of an electric arc, radiation energy, or an exothermic reaction is utilized to melt or oxidize a metal at an accelerated rate to achieve a cut. Several processes use the arc’s heat to cut metals, including shielded metal arc, air carbon arc, plasma arc, gas tungsten arc, and gas metal arc.

Electron beams and laser beams use radiation energy to achieve the Cutting of metals. Oxy-fuel gas flame in conjunction with oxygen jet is utilized to initiate and sustain an exothermic oxidizing reaction which generates enough heat and affects the parting of metals, low carbon ferrous alloys. Out of these processes oxy- acetylene, air-carbon arc, and plasma arc are the three major thermal cutting processes used in the industry.

Conventional machining processes – and several more high-tech methods – can apply stress on the part, creating microcracks, geometric or thermal distortion, and even changing the material’s composition. These processes also stress the tool, which increases machining time, and costs and decreases the repeatability of the part.

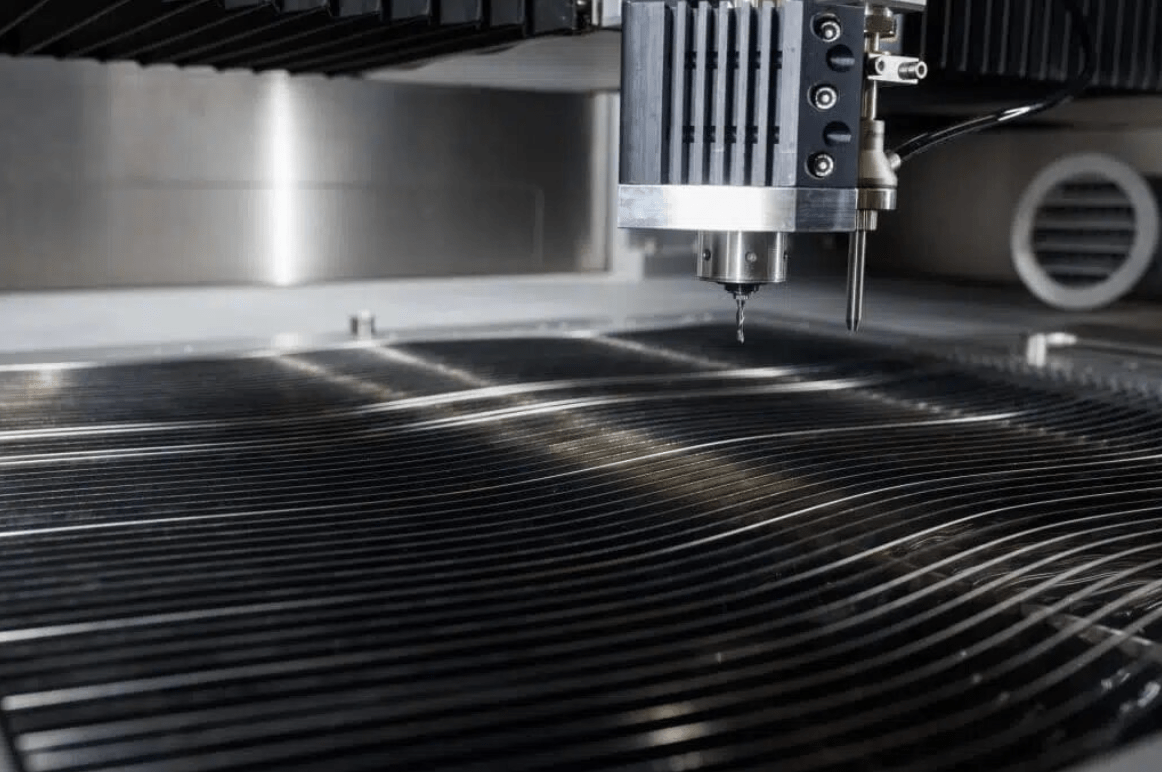

Finepart’s micro abrasive waterjet is not heat-based and introduces no substantial thermal load on the part, eliminating the influence of thermal stresses on the piece.

On the other hand, machining processes such as electric discharge machining (EDM) and laser cutting or machining use heat to shape the workpiece. This heating creates recast layers, heat-affected zones, and microcracking – all detrimental to the part performance.

Even conventional machining processes such as milling, turning, and grinding can introduce unwanted heat into the part. The non-thermal process preserves the material’s makeup and the intended shape of the piece and prevents compromising its strength.

One company that has been in this line of business for quite some time is Finepart. It is known for producing small parts with non-thermal cutting technology that provides the ultimate precision, quality, and cutting speed in virtually all materials. Unlike many companies working in the same line, they use flexible machine tool designs that can be placed in any CNC workshop.

Making sure that the earth’s environment is not affected by making our lives easy is one thing we need to keep in mind. Eco-friendly cutting technology is one of the reasons why Finepart is more suggested to get the services done. Less material waste and higher cost savings are other examples of such reasons.

- Superior surface finish and edge quality

- Ultra-high Precision

- 3D Cutting

- Non-thermal Cutting

- It cuts virtually any material

- High cutting depth to jet diameter ratio

- Possibility of ablation

- Easy to use and low-cost setup

Above mentioned are some bullet points that Finepart keeps in mind, and all these things are eventually helping this company reach heights of success.

Tech

The Importance of Cyber Hygiene: Tips from HelpRansomware Experts

Byline: Katreen David

In the digital age, the adage “an ounce of prevention is worth a pound of cure” has never been more relevant.

For Juan Ricardo Palacio and Andrea Baggio of HelpRansomware, the battle against digital threats is a daily reality. Founded in response to the growing menace of ransomware, HelpRansomware has made it its mission to recover data while educating the public on the importance of cyber hygiene.

“Preventing a cyberattack before it happens is crucial. We can safeguard digital assets more effectively by nipping the threat in the bud through vigilant monitoring and proactive measures,” says Baggio.

The Growing Threat of Cybercrime

Cyber threats have become increasingly pervasive and sophisticated, impacting businesses and individuals alike. According to research, there are an estimated 2,000 cyberattacks per day globally. This equates to over 800,000 cyber crimes annually. In line with this, the worldwide cost of cybercrime is projected to reach the $23 trillion mark by 2027.

This alarming figure highlights the critical need for robust cybersecurity practices. HelpRansomware has responded to this challenge by accentuating the importance of preventive measures. “Our goal is to create a safer digital environment where cyber hygiene is as natural as brushing your teeth,” says Palacio.

Cyber Clean: Maintaining Digital Hygiene

HelpRansomware advocates for a proactive outlook on cybersecurity. It offers practical tips for maintaining good cyber hygiene, such as regularly updating software, using strong and unique passwords, developing risk management plans, and educating employees about phishing scams.

“Cyber hygiene is about taking small, consistent actions to protect your digital assets,” explains Palacio. “When we practice good cyber hygiene, the chances of cyber attacks occurring shrink significantly.”

Businesses can significantly reduce cyberattack vulnerability by integrating these practices into daily routines.

HelpRansomware’s Role in Promoting Cyber Hygiene

Beyond recovery services, HelpRansomware is dedicated to raising awareness and providing education on cybersecurity best practices. It conducts workshops and seminars to help organizations understand the importance of cyber hygiene. This unique initiative mirrors the company’s sincere efforts toward shielding the world from the dark side of the web.

“Education is the first line of defense against cyber threats,” emphasizes Baggio. “Francis Bacon’s famous quote will always ring true in every industry: ‘Knowledge is power’.”

HelpRansomware’s efforts are power moves across the board that help businesses recover from attacks. Its checkmate move, however, is its vision to build a culture of prevention that can safeguard against future threats.

In an era where cyber threats lurk around every unlikely corner of the internet, the importance of cyber hygiene cannot be overstated. Through its innovative solutions and educational initiatives, HelpRansomware is leading the pack in promoting better cybersecurity practices. “We believe that a well-informed and vigilant community can defeat cybercrime,” concludes Baggio.

HelpRansomware’s proactive stance on cyber hygiene is setting new standards in the industry. Through education and preventive practices, Andrea Baggio and Juan Ricardo Palacio are fortifying the digital community, making sure that future cyber threats are met with informed and resilient defenses. Cleanliness matters in both the tangible and digital world.

-

Tech4 years ago

Tech4 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle6 years ago

Lifestyle6 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle4 years ago

Lifestyle4 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health6 years ago

Health6 years agoCBDistillery Review: Is it a scam?

-

Entertainment6 years ago

Entertainment6 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free