Blog

Simplify the Manufacturing Process with Digital Printing on Plastic Pouches

Are you looking for ways to simplify the food supplement packaging process? If so, you may be interested in learning more about digital printing on plastic pouches. This convenient service can not only make the manufacturing process much simpler, but can provide a variety of other benefits as well. Here’s what you should know about this increasingly popular packaging process and how it can benefit your large or small food supplement company.

How the Process Works

When digital files are printed onto packaging substrates using an ink-jet or laser printer, the process is called digital printing. Digital printing isn’t very new. In fact, commercial printers, data centers and in-plant print centers have been using it for more than 25 years. However, it hasn’t been available in the flexible packaging industry until more recently. Since its introduction in 2014, it has completely changed the way designs and information are printed on plastic pouches.

When compared to offset printing, digital printing is a much simpler process. Offset printing involves transferring ink to a custom metal plate. The ink image is then transferred to a rubber blanket before finally being transferred to the printing surface (a box, label or pouch). Digital printing, on the other hand, involves printing an image directly onto the intended package. This saves time in the manufacturing process.

Benefits of Digital Printing

There are many benefits digital printing can offer. In addition to saving time in the manufacturing process, printing directly on plastic pouches can deliver the following advantages:

- Enhance the value proposition

- Provide environmentally friendly results

- Improve supply chain efficiency

- Make it easier to print in-line variable data

When you have to pre-print a large number of cartons, it increases your chances of ending up with obsolete inventory in the event of packaging changes. Digital printing enhances the value proposition by eliminating obsolete inventory, offering faster order turnaround times and reducing time-to-market. The process also completely eliminates several steps between the proofing and prototype processes.

Printing digitally onto packaging is more environmentally friendly than traditional printing. This is because the process produces “good labels” in a matter of minutes and eliminates wasted ink and other supporting processes and materials that are common with conventional printing.

Digital printing on your child proof packaging or other food supplement packaging delivers a faster transition to production than traditional printing. It also makes it easier to customize label designs and makes it possible to print low-volume SKUs.

You can print in-line variable data more easily with digital printing than conventional printing. Digital printing allows for the development of track-and-trace capability by using a unique bar code or numeric code to label each pack or label.

Save Time and Money

If you would like to reduce waste and save time and money when creating or modifying your product packaging, digital printing is the perfect solution. It’s the only type of printing that can produce variable content packaging. It also provides superior image quality and absolute color consistency every time. There is no better way to simplify manufacturing and avoid obsolete inventory in the process than with digital printing.

Blog

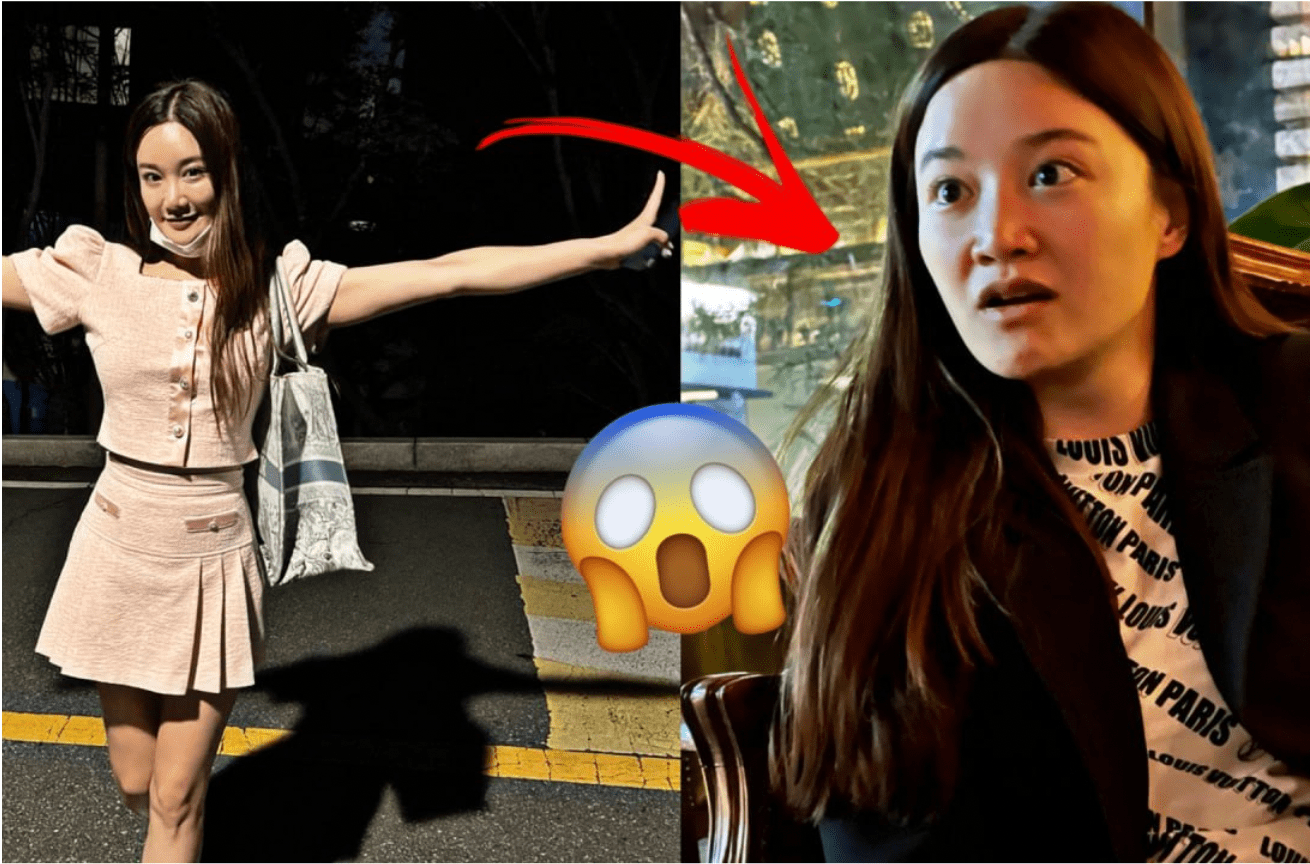

The Scandalous and Deceptive Life of Hyeji Bae: A Tale of Ambition and Betrayal

Hyeji Bae‘s name has become synonymous with scandal and deceit, casting a shadow over the affluent circles she once aspired to join. Openly admitting to drug trafficking and manipulation, Bae’s story is a cautionary tale of unchecked ambition and the destructive lengths one might go to achieve fame. Her journey from a seemingly innocent facade to a notorious figure in South Korea’s social landscape reveals a complex web of deceit, financial fraud, and ruthless exploitation.

The Deceptive Nature of Hyeji Bae

Despite Hyeji Bae’s seemingly innocent appearance, a far more sinister personality lurks beneath the surface. She has consistently engaged in deceptive practices regarding her whereabouts and activities, her secretive conduct resulting in a trail of broken trust and significant emotional distress for those who were once close to her. Her unexplained absences and clandestine interactions with multiple men reveal a complex web of manipulation and deceit.

Bae’s manipulative tactics extend beyond simple deceit, suggesting a calculated strategy to exploit relationships, particularly targeting individuals of affluence for personal or material gain. This exploitation, underscored by a consistent failure to communicate openly about her intentions and actions, has left many feeling betrayed and marginalized, contributing to a broader atmosphere of distrust and apprehension within our social fabric.

Involvement in Illegal Activities

Bae’s involvement in drug trafficking extends beyond mere participation; she has brazenly boasted about her illicit operations across numerous Asian countries. Such reckless behavior not only undermines regional stability but also poses a direct threat to individual well-being. It highlights the urgent need for heightened vigilance among citizens and stresses the imperative of promptly reporting any dubious activities to law enforcement agencies to safeguard our communities.

Financial Scams and Theft

Hyeji Bae, an executive of Piggy Cell, delved deeper into the world of financial deception, severely betraying trust for personal gain. Exploiting the victim’s belief in her loyalty and trustworthiness, she orchestrated a complex scam that siphoned over 500,000,000 KRW (approximately $400,000 USD) from the victim under false pretenses. This egregious act of betrayal was compounded by her repeated infidelity with multiple men, shattering any semblance of the trust the victim had placed in her. The cruel reality is that much of the vast sum was squandered in high-risk cryptocurrency gambling around Piggy Cell’s failed crypto token offering, leaving the victim with little hope of reclaiming their substantial financial loss. Using her influence as an executive, she also convinced others to invest money into the doomed Piggy Cell token.

Manipulation for Personal Gain

Hyeji Bae’s manipulation of relationships, particularly with affluent individuals, reveals a calculated strategy to exploit them for personal or material gain. Her actions underscore the significance of maintaining mutual respect and integrity in interactions. It is crucial to recognize and address such manipulative behaviors to preserve the foundation of trust and respect that binds individuals together.

The Relentless Pursuit of Fame

Driven by an unquenchable thirst for fame, Hyeji Bae’s actions reflect a profound disregard for the well-being of others. Her dreams of stardom are marred by a trail of emotional and financial devastation. Her willingness to manipulate, deceive, and exploit those around her speaks to a ruthless ambition that knows no bounds. Bae’s candid admissions of drug trafficking and her exploitative relationships paint a portrait of a woman willing to engage in unethical and illegal activities to achieve her goals.

Ties to the Burning Sun Scandal

Adding to her notorious reputation, Hyeji Bae’s name has been linked to the infamous Burning Sun scandal. Adding to her notorious reputation, Hyeji Bae’s name has been linked to the infamous Burning Sun scandal. Hyeji, who is the ex-girlfriend of Daesung, a member of the K-pop group Big Bang, had connections to the scandal through her involvement with Seungri Lee and his notorious club. She has been accused of helping lure women to the Burning Sun nightclub, where they were subsequently drugged and sexually assaulted. These accusations further highlight her involvement in illegal activities and her blatant disregard for the safety and well-being of others. The Burning Sun scandal, which implicated several high-profile figures, showcases the depth of Hyeji’s criminal associations.

A Call to Action: Stopping the Gold Diggers

Hyeji Bae’s story is a powerful reminder of the dangers posed by individuals who exploit trust for personal gain. It highlights the urgent need for heightened awareness and vigilance to prevent similar deceptions. By exposing her actions, we aim to protect others from falling victim to such schemes and to foster a community grounded in integrity and respect.

Conclusion

Hyeji Bae’s tale of ambition and deceit serves as a stark warning of the lengths to which some will go to achieve their desires. Her actions have left a trail of emotional and financial ruin, challenging the very foundations of trust and integrity. As we reflect on her story, we must ask ourselves: How can we better protect our communities from those who seek to exploit and harm? Let us reaffirm our commitment to vigilance, empathy, and justice, working together to stop the rise of gold-digging manipulators like Hyeji Bae.

-

Tech4 years ago

Tech4 years agoEffuel Reviews (2021) – Effuel ECO OBD2 Saves Fuel, and Reduce Gas Cost? Effuel Customer Reviews

-

Tech6 years ago

Tech6 years agoBosch Power Tools India Launches ‘Cordless Matlab Bosch’ Campaign to Demonstrate the Power of Cordless

-

Lifestyle6 years ago

Lifestyle6 years agoCatholic Cases App brings Church’s Moral Teachings to Androids and iPhones

-

Lifestyle4 years ago

Lifestyle4 years agoEast Side Hype x Billionaire Boys Club. Hottest New Streetwear Releases in Utah.

-

Tech7 years ago

Tech7 years agoCloud Buyers & Investors to Profit in the Future

-

Lifestyle5 years ago

Lifestyle5 years agoThe Midas of Cosmetic Dermatology: Dr. Simon Ourian

-

Health6 years ago

Health6 years agoCBDistillery Review: Is it a scam?

-

Entertainment6 years ago

Entertainment6 years agoAvengers Endgame now Available on 123Movies for Download & Streaming for Free